-

摘要:

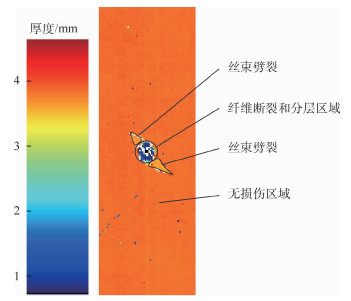

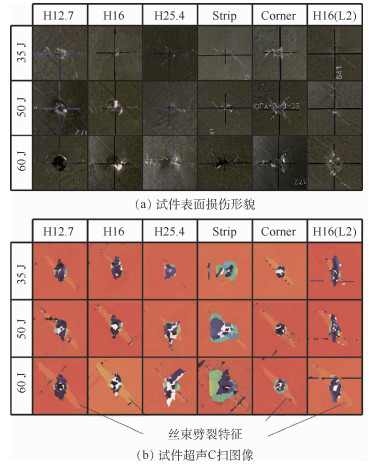

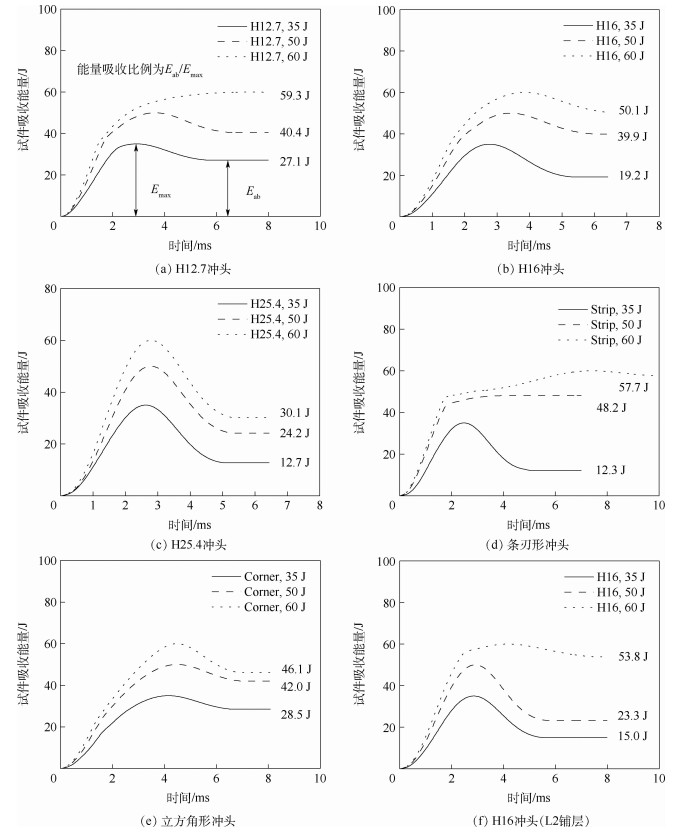

通过实验研究了复合材料层压板的低速冲击行为和剩余拉伸强度。首先,通过冲击实验研究了冲头类型和铺层形式对层压板冲击响应的影响,并通过凹坑深度、损伤投影面积、冲击力和冲击能量转化等对冲击损伤特性进行评估。其次,通过准静态拉伸实验调查了层压板的冲击后拉伸响应和剩余拉伸强度。最后,分析了冲头类型和铺层形式对层压板冲击行为和剩余拉伸强度的影响机理。结果表明:冲头类型对层压板冲击损伤的影响与冲击接触面投影面积和凹坑深度的函数关系密切相关;在较高的冲击能量下,条刃形冲头是造成损伤的关键冲击威胁,而立方角形冲头造成的损伤相对不严重;铺层形式对层压板的冲击损伤阻抗性能和拉伸断裂形貌有明显的影响。

Abstract:The low-velocity impact behavior and residual tensile strength of composite laminates are experimentally studied in this paper. Firstly, the effects of impactor type and layup type on the impact responses of laminates are investigated by impact tests, and damage characteristics are evaluated by using the dent depth, damage projection area, impact force and impact energy translation. Secondly, the tensile response and residual tensile strength of the laminates after impact are investigated by quasi-static tensile tests. Finally, the mechanism of the effects of impactor type and layup type on the impact behavior and residual tensile strength of the laminates are analyzed. The results indicate that: the effect of impactor type on impact damage of composite laminate is closely related to the function of the projection area of impact contact surface with the dent depth; under the condition of high impact energy, the strip impactor is a critical impact threat to damage, while the damage caused by corner impactor is relatively not serious; the type of layup has a remarkable influence on the impact damage resistance performance and tensile fracture morphology of the laminates.

-

Key words:

- composite /

- laminate /

- impactor shape /

- impact behavior /

- tensile strength

-

表 1 试件铺层

Table 1. Layup of test specimens

代码 铺层顺序 名义厚度/mm L1 [45/-45/90/45/-45/45/-45/0/45/-45]S 3.740 L2 [45/0/-45/0/90/0/45/0/-45/0]S 3.740 注:s表示铺层对称。 表 2 实验安排

Table 2. Test arrangement

铺层代码 冲头代码 冲头描述 冲击能量/J 备注 L1 N/A N/A N/A 拉伸实验 H12.7 半球形冲头,Ф=12.7 mm 35, 50, 60 冲击后拉伸实验 H16 半球形冲头,Ф=16 mm 35, 50, 60 冲击后拉伸实验 H25.4 半球形冲头,Ф=25.4 mm 35, 50, 60 冲击后拉伸实验 L2 Strip 条刃形冲头 35, 50, 60 冲击后拉伸实验 Corner 立方角形冲头 35, 50, 60 冲击后拉伸实验 H16 半球形冲头,Ф=16 mm 35, 50, 60 冲击后拉伸实验 注:N/A表示不适用。 表 3 冲击实验结果汇总

Table 3. Summary of impact test results

铺层代码 冲头代码 凹坑深度/mm 损伤投影面积/mm2 35 J 50 J 60 J 35 J 50 J 60 J H12.7 1.038 2.110 穿透 1 629 2 285 2 969 L1 H16 0.379 1.274 2.454 1 232 1 985 2 639 H25.4 0.246 0.434 0.861 972 1 806 2 165 Strip 0.207 2.584 穿透 2 000 2 754 3 021 L2 Corner 1.940 2.117 2.530 1 046 1 696 1 961 H16 0.363 1.051 1.636 1 196 2 050 2 723 表 4 拉伸实验结果汇总

Table 4. Summary of tensile test results

铺层代码 冲头代码 剩余拉伸强度/MPa 35 J 50 J 60 J H12.7 357 355 337 L1 H16 404 372 357 H25.4 459 399 367 Strip 427 305 286 L2 Corner 388 369 355 H16 1 021 928 824 -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1): 1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU S Y. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica, 2007, 24(1): 1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] 杜善义, 关志东. 我国大型客机先进复合材料技术应对策略思考[J]. 复合材料学报, 2008, 25(1): 1-10. doi: 10.3321/j.issn:1000-3851.2008.01.001DU S Y, GUAN Z D. Strategic considerations for development of advanced composite technology for large commercial aircraft in China[J]. Acta Materiae Compositae Sinica, 2008, 25(1): 1-10(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.01.001 [3] LIU H B, FALZON B G, TAN W. Experimental and numerical studies on the impact response of damage-tolerant hybrid unidirectional/woven carbon-fibre reinforced composite laminates[J]. Composites Part B: Engineering, 2018, 136: 101-118. doi: 10.1016/j.compositesb.2017.10.016 [4] 林智育, 许希武. 含冲击损伤复合材料加筋层板压缩剩余强度[J]. 航空学报, 2009, 30(1): 56-61. doi: 10.3321/j.issn:1000-6893.2009.01.008LIN Z Y, XU X W. Residual compressive strength of stiffened composite laminates with impact damage[J]. Acta Aeronautica et Astronautica Sinica, 2009, 30(1): 56-61(in Chinese). doi: 10.3321/j.issn:1000-6893.2009.01.008 [5] AHN S S, HONG S W, KOO J M, et al. Evaluation of compressive residual strength in composite material under impact damage[J]. Transactions of the Korean Society of Mechanical Engineers, 2013, 37(4): 503-509. doi: 10.3795/KSME-A.2013.37.4.503 [6] ANDREWA J J, SRINIVASANA S M, AROCKIARAJAN A. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: A critical review[J]. Composite Structures, 2019, 224(9): 1-26. [7] CMH-17 Committee. Composite materials handbook. Vol 3: Polymer matrix composites materials usage, design, and analysis[M]. Detroit: SAE International, 2012: 2-33. [8] DELANEY M P, FUNG S Y K, KIM H. Dent depth visibility versus delamination damage for impact of composite panels by tips of varying radius[J]. Journal of Composite Materials, 2018, 52(19): 2691-2705. doi: 10.1177/0021998317752502 [9] MITREVSKI T, MARSHALL I H, THOMSON R, et al. The influence of impactor shape on the damage to composite laminates[J]. Composite Structures, 2006, 76: 116-122. doi: 10.1016/j.compstruct.2006.06.017 [10] MITREVSKI T, MARSHALL I H, THOMSON R, et al. Low-velocity impacts on preloaded GFRP specimens with various impactor shapes[J]. Composite Structures, 2006, 76: 209-217. doi: 10.1016/j.compstruct.2006.06.033 [11] YU Z F, GAO S J. Increase of contact radius due to deflection in low velocity impact of composite laminates and prediction of delamination threshold load[J]. Composite Structures, 2016, 147: 286-293. doi: 10.1016/j.compstruct.2016.03.029 [12] AMARO A M, REIS P N B, MAGALHAES A G, et al. The effect of the impactor diameter and boundary conditions on low velocity impact composites behavior[J]. Applied Mechanics and Materials, 2007, 7: 217-222. [13] BULENT M I, BINNUR G K, MEHMET E D, et al. Impactor diameter effect on low velocity impact response of woven glass epoxy composite plates[J]. Composites Part B, 2013, 50: 325-332. doi: 10.1016/j.compositesb.2013.02.024 [14] ALI K, MEHMET S, HALIL M E, et al. Effect of impactor shapes on the low velocity impact damage of sandwich composite plate: Experimental study and modelling[J]. Composites Part B, 2016, 86: 143-151. doi: 10.1016/j.compositesb.2015.09.032 [15] MILI F, NECIB B. The effect of stacking sequence on the impact-induced damage in cross-ply E-glass/epoxy composite plates[J]. Archive of Applied Mechanics, 2009, 79(11): 1019-1031. doi: 10.1007/s00419-008-0272-z [16] CZANOCKI P. Delamination resistance of laminates with various stacking sequences against low velocity impacts[J]. Solid State Phenom, 2015, 240: 143-148. doi: 10.4028/www.scientific.net/SSP.240.143 [17] ZHOU J W, LIAO B B, SHI Y Y, et al. Low-velocity impact behavior and residual tensile strength of CFRP laminates[J]. Composites Part B, 2019, 161: 300-313. doi: 10.1016/j.compositesb.2018.10.090 [18] 邹健, 程小全, 陈浩, 等. 二维织物增强层合板高速冲击后拉伸性能模拟[J]. 北京航空航天大学学报, 2008, 34(6): 638-642. https://bhxb.buaa.edu.cn/CN/Y2008/V34/I06/638ZOU J, CHENG X Q, CHEN H, et al. Tensile properties simulation of two-dimensional woven reinforced composite laminates after high velocity impact[J]. Journal of Beijing University of Aeronautics and Astronautics, 2008, 34(6): 638-642(in Chinese). https://bhxb.buaa.edu.cn/CN/Y2008/V34/I06/638 [19] 程小全, 康炘蒙, 邹健, 等. 平面编织复合材料层合板低速冲击后的拉伸性能[J]. 复合材料学报, 2008, 25(5): 163-168. doi: 10.3321/j.issn:1000-3851.2008.05.027CHENG X Q, KANG X M, ZHOU J, et al. Tensile properties of plane woven composite laminates after low velocity impact[J]. Acta Materiae Compositae Sinica, 2008, 25(5): 163-168(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.05.027 [20] 屈天骄, 郑锡涛, 范献银, 等. 复合材料层合板低速冲击损伤影响因素分析[J]. 航空材料学报, 2011, 31(6): 81-86.QU T J, ZHENG X T, FAN X Y. Exploration of several influence factors of low-velocity impact damage on composite laminates[J]. Journal of Aeronautical Materials, 2011, 31(6): 81-86(in Chinese). [21] AKTAS M, ATAS C, ICTEN B M, et al. An experimental investigation of the impact response of composite laminates[J]. Composite Structure, 2009, 87: 307-313. doi: 10.1016/j.compstruct.2008.02.003 [22] EVCI C, GULGEC M. An experimental investigation on the impact response of composite materials[J]. International Journal of Impact Engineering, 2012, 43: 40-51. doi: 10.1016/j.ijimpeng.2011.11.009 [23] LI X K, LIU P F. Experimental analysis of low-velocity impact behaviors of carbon fiber composite laminates[J]. Journal of Failure Analysis and Prevention, 2017, 17(6): 1126-1130. doi: 10.1007/s11668-017-0350-z [24] XU Z, YANG F, GUAN Z W, CANTWELL W J. An experimental and numerical study on scaling effects in the low velocity impact response of CFRP laminates[J]. Composite Structure, 2016, 154: 69-78. doi: 10.1016/j.compstruct.2016.07.029 [25] BALASUBRAMANI V, BOOPATHY S R. Prediction of residual tensile strength of laminated composite plates after low velocity impact[J]. ARPN Journal of Engineering and Applied Sciences, 2014, 9: 320-325. [26] KHAN H A, NIGAR M, CHAUDHRY I A. Tensile behavior of unidirectional carbon reinforced composites for aerospace structures under varying strain rates[J]. Applied Mechanics and Materials, 2015, 798: 357-361. doi: 10.4028/www.scientific.net/AMM.798.357 [27] MOSALLAM A, SLENK J, KREINER J. Assessment of residual tensile strength of carbon/epoxy composites subjected to low-energy impact[J]. Journal of Aerospace Engineering, 2008, 21(4): 249-258. doi: 10.1061/(ASCE)0893-1321(2008)21:4(249) [28] ASTM Committee. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D7136/D7136M-15[S]. West Conshohocken: ASTM International, 2015. [29] ASTM Committee. Standard test method for compressive residual strength properties of damaged polymer matrix composite plates: ASTM D3039/D3039M-14[S]. West Conshohocken: ASTM International, 2012. [30] DANIEL W, HYONNY K. Effect of impactor radius on low-velocity impact damage of glass/epoxy composites[J]. Journal of Composite Materials, 2012, 46(25): 3137-3149. doi: 10.1177/0021998312436991 [31] HITCHEN S, KEMP R. The effect of stacking sequence on impact damage in a carbon fiber/epoxy composite[J]. Composites, 1995, 26(3): 207-214. doi: 10.1016/0010-4361(95)91384-H [32] LI T, YANG Y, YU X, et al. Micro-structure response and fracture mechanisms of C/SiC composites subjected to low-velocity ballistic penetration[J]. Ceramics International, 2017, 43: 6910-6918. [33] LI T, MO J, YU X, et al. Mechanical behavior of C/SiC composites under hypervelocity impact at different temperatures: Micro-structures, damage and mechanisms[J]. Composites Part A: Applied Science and Manufacturing, 2016, 88: 19-26. doi: 10.1016/j.compositesa.2016.05.015 -

下载:

下载: