Steady-state experiment and numerical simulation on flow and heat transfer of a rotating cavity with axial flow

-

摘要:

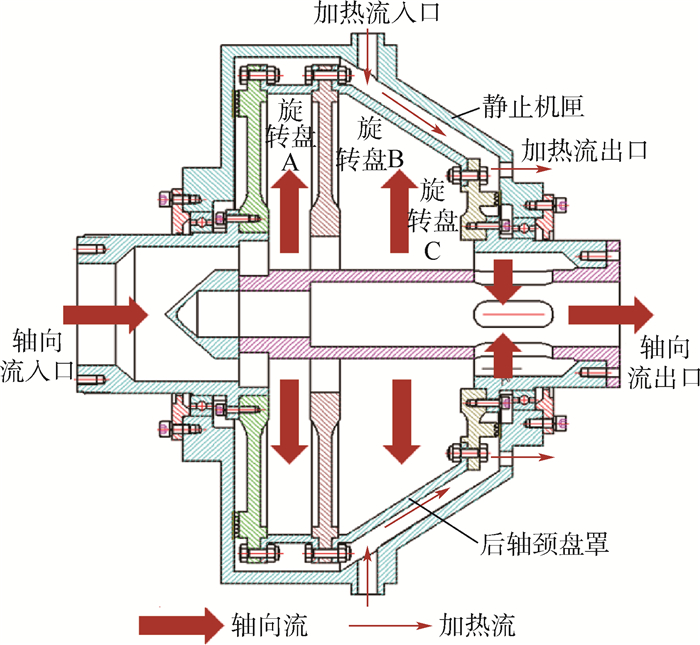

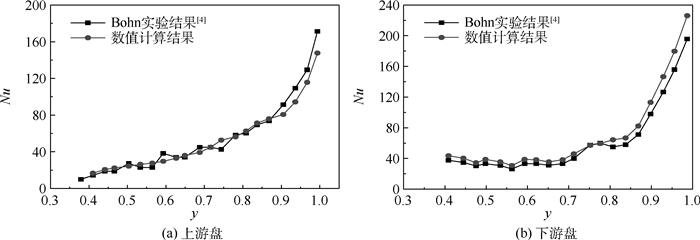

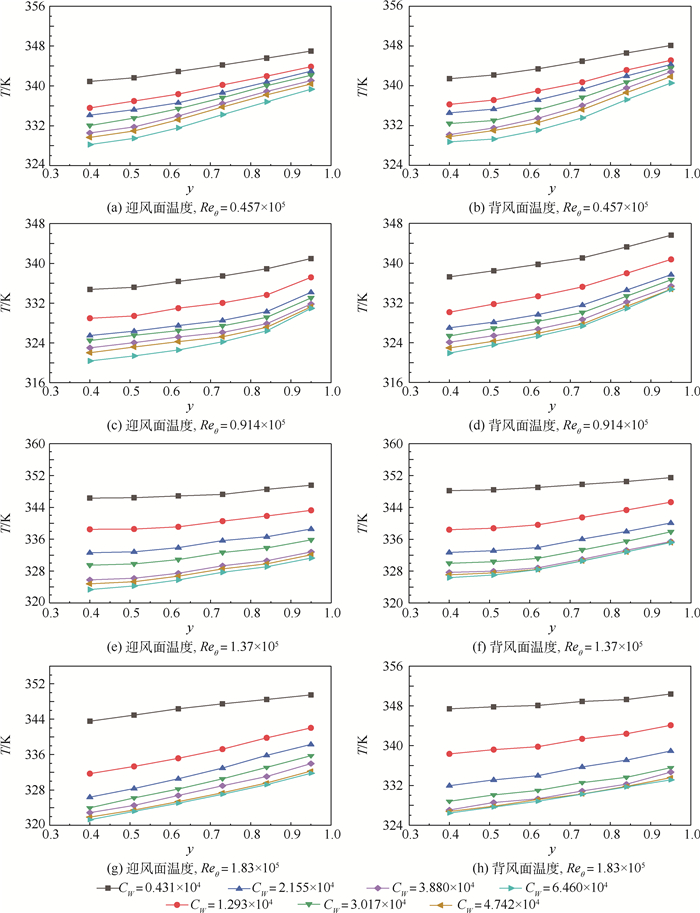

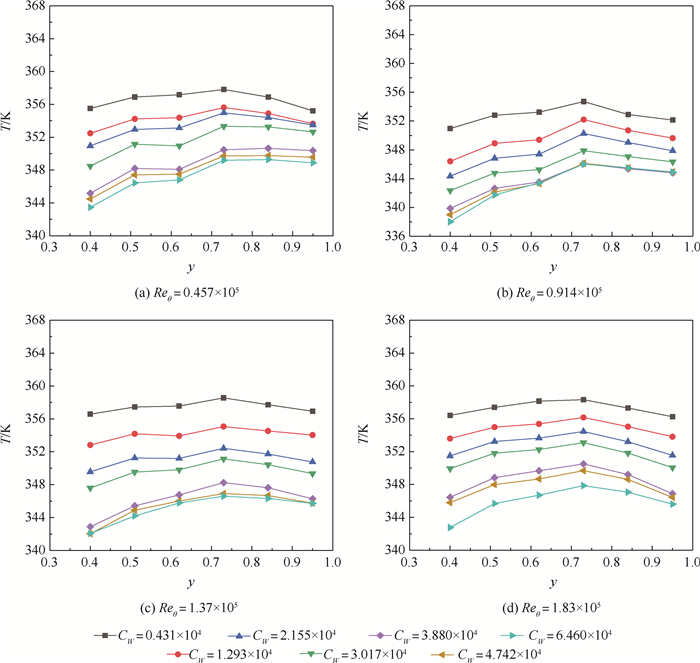

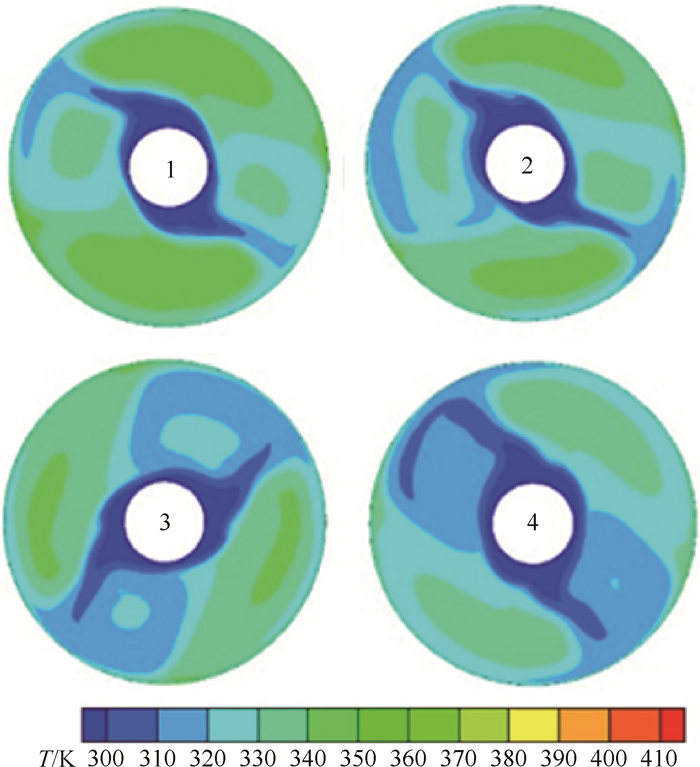

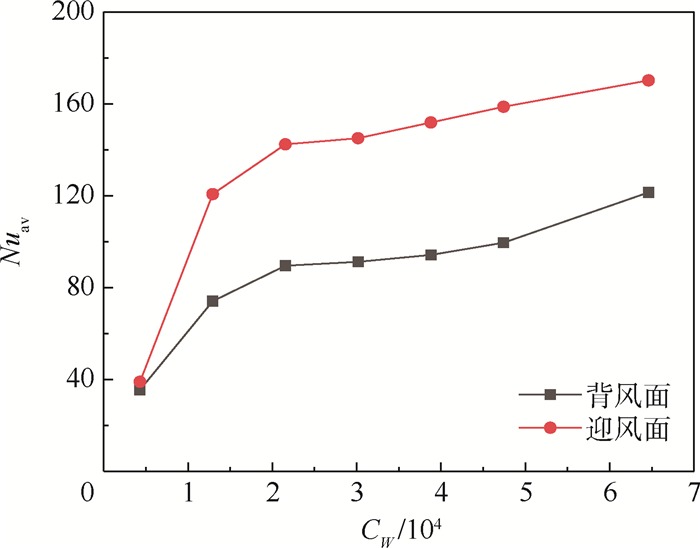

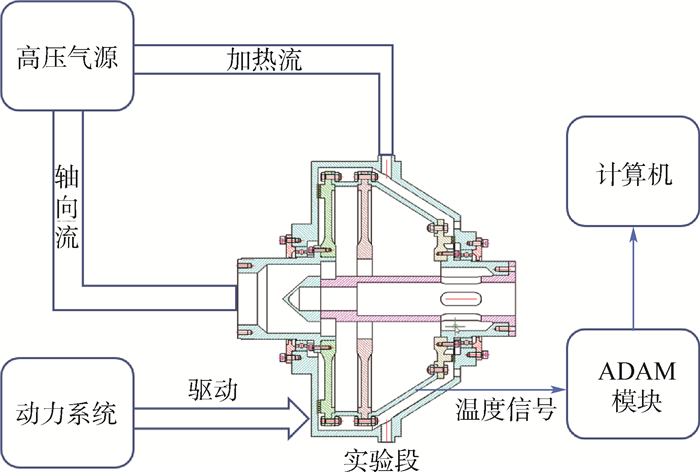

通过开展稳态实验及数值模拟探究了轴向通流旋转盘腔的流动结构与换热特性。通过改变流量系数、旋转雷诺数等参数,探究不同工况下旋转盘两侧及盘罩内侧壁面温度和努塞尔数的径向分布规律。结果表明:在轮缘加热的状态下,旋转盘两侧温度径向分布均呈凹函数形态,且旋转盘迎风面换热强度普遍高于背风面;后轴颈盘罩向两端旋转盘导热,其壁面温度径向分布呈"中间高、两侧低"的状态;随着轴向流量系数的增大,盘腔内部气体对流加剧,径向臂及涡对结构更加明显,旋转盘及轴颈表面换热效果增强;旋转盘腔内的流动换热特性受强迫对流和类Rayleigh-Benard对流2种机理的共同影响。

Abstract:The steady-state experiment and numerical simulation were carried out to investigate the flow structure and heat transfer characteristics in the rotating cavity with axial flow. By changing the axial flow coefficient, rotating Reynolds number, etc., the radial distribution of temperature and Nusselt number on both sides of the disk and the inner side of the disk cone under different working conditions was explored. The results show that: the radial distribution of temperature on both sides of the disk is concave, and the heat transfer intensity on the upwind side of the disk is generally higher than that on the leeward side. The cone disk conducts heat conduction to the disks on both ends, and the radial distribution of the wall surface temperature is high in the middle and low on both sides. With the increase of the axial flow coefficient, the gas convection inside the disk cavity was intensified, the radial arm and vortex pair became explicit, and the heat transfer effect on the surface of the rotating disk and the cone disk was enhanced. The flow heat transfer characteristics in the cavity of the rotating disk are influenced by forced convection and Rayleigh-Benard like convection.

-

Key words:

- rotating cavity /

- axial flow /

- cone disk /

- flow structure /

- heat transfer characteristics

-

表 1 实验工况

Table 1. Working conditions of experiment

m/(kg·h-1) CW ω/(r·min-1) Reθ 50 4 310.6 200 45 681.3 150 12 931.9 400 91 362.6 250 21 553.2 600 137 044.0 350 30 174.5 800 182 725.3 450 38 795.8 550 47 417.0 750 64 659.6 -

[1] OWEN J M, PINCOMBE J R. Vortex breakdown in a rotating cylindrical cavity[J]. Journal of Fluid Mechanics, 1979, 90(1): 109-127. doi: 10.1017/S0022112079002093 [2] FARTHING P R, LONG G A, OWEN J M, et al. Rotating cavity with axial throughflow of cooling air: Flow structure[J]. Journal of Turbomachinery, 1992, 114(1): 237-246. doi: 10.1115/1.2927991 [3] ALEXIOU A. Flow and heat transfer in gas turbine h. p. compressor internal air systems[D]. Sussex: University of Sussex, 2000. [4] BOHN D E, DEUTSCH G N, SIMON B, et al. Flow visualisation in a rotating cavity with axial throughflow[C]//ASME Turbo Expo: Power for Land, Sea, & Air. New York: ASME, 2000. [5] 田淑青, 陶智, 丁水汀, 等. 轴向通流旋转盘腔内流动不稳定性研究[J]. 北京航空航天大学学报, 2005, 31(4): 393-396. doi: 10.3969/j.issn.1001-5965.2005.04.005TIAN S Q, TAO Z, DING S T, et al. Investigation of flow instability in rotating cavity with axial throughflow of cooling air[J]. Journal of Beijing University of Aeronautics and Astronautics, 2005, 31(4): 393-396(in Chinese). doi: 10.3969/j.issn.1001-5965.2005.04.005 [6] 田淑青, 陶智, 丁水汀, 等. 轴向通流旋转盘腔内换热的数值模拟[J]. 航空动力学报, 2005, 20(4): 656-661.TIAN S Q, TAO Z, DING S T, et al. Numerical investigation on heat transfer in a rotating cavity with axial throughflow of cooling air[J]. Journal of Aerospace Power, 2005, 20(4): 656-661(in Chinese). [7] 田淑青, 陶智, 丁水汀, 等. 轴向通流旋转盘腔内类Rayleigh-Benard对流稳定性研究[J]. 热科学与技术, 2003, 2(3): 260-265. doi: 10.3969/j.issn.1671-8097.2003.03.015TIAN S Q, TAO Z, DING S T, et al. Investigation of Rayleigh-Benard-like convection stabilities in rotating cavity with axial throughflow of cooling air[J]. Journal of Thermal Science and Technology, 2003, 2(3): 260-265(in Chinese). doi: 10.3969/j.issn.1671-8097.2003.03.015 [8] PITZ D B, CHEW J W, MARXEN O. Effect of an axial throughflow on buoyancy-induced flow in a rotating cavity[J]. International Journal of Heat and Fluid Flow, 2019, 80: 108468. doi: 10.1016/j.ijheatfluidflow.2019.108468 [9] FARTHING P R, LONG C A, OWEN J M, et al. Rotating cavity with axial throughflow of cooling air: Heat transfer[J]. Journal of Turbomachinery, 1992, 114(1): 229-236. doi: 10.1115/1.2927990 [10] OWEN J M, POWELL J. Buoyancy induced flow in a heated rotating cavity[J]. Journal of Engineering for Gas Turbines and Power, 2006, 128(1): 128-134. doi: 10.1115/1.2032451 [11] OWEN J M, BILIMORIA E D. Heat transfer in rotating cylindrical cavities[J]. Journal of Mechanical Engineering Science, 1977, 19(4): 175-187. doi: 10.1243/JMES_JOUR_1977_019_038_02 [12] LONG C A, TUCKER P G. Shroud heat transfer measurements from a rotating cavity with an axial throughflow of air[J]. Journal of Turbomachinery, 1994, 116(3): 525-534. doi: 10.1115/1.2929441 [13] TUCKER P G, LONG C A. Fluid temperature distributions in a rotating cavity with an axial throughflow[J]. International Communications in Heat and Mass Transfer, 1998, 25(4): 511-520 doi: 10.1016/S0735-1933(98)00038-4 [14] OWEN J M, TANG H. Theoretical model of Buoyancy-induced flow in rotating cavities[J]. Journal of Turbomachinery, 2015, 137(11): 111005. doi: 10.1115/1.4031353 [15] 徐国强, 张笙, 罗翔, 等. 高位垂直进气径向出流旋转盘腔换热的实验研究[J]. 航空动力学报, 2006, 21(5): 820-823.XU G Q, ZHANG S, LUO X, et al. Experimental investigation on heat transfer in shrouded rotating disk with high-positioned air inflow[J]. Journal of Aerospace Power, 2006, 21(5): 820-823(in Chinese). [16] 曹楠, 窦志伟, 罗翔, 等. 轴向通流旋转盘腔换热特性[J]. 航空动力学报, 2018, 33(5): 1178-1185.CAO N, DOU Z W, LUO X, et al. Heat transfer characteristics of a rotating cavity with axial throughflow of cooling air[J]. Journal of Aerospace Power, 2018, 33(5): 1178-1185(in Chinese). [17] ALEXIOU A, HILLS N J, LONG C A, et al. Heat transfer in high-pressure compressor gas turbine internal air systems: A rotating disc-cone cavity with axial throughflow[J]. Experimental Heat Transfer, 2000, 13(4): 299-328. -

下载:

下载: