-

摘要:

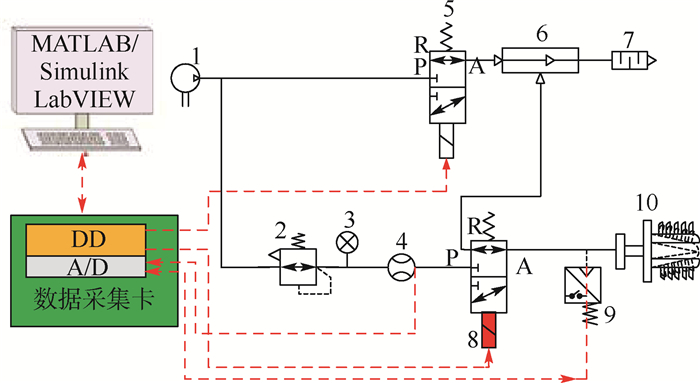

通过工控机的数据采集系统,结合传感器技术、信号处理技术等,搭建设备建立气体压力、流量等参数的在线测量系统,实现对测控系统的调节和控制。首先,分别采集柔性夹爪在收缩和扩张时不同初始压力下的压力与流量;然后,通过SigmaPlot绘出柔性夹爪压力流量图,并对柔性夹爪流量压力输出特性进行分析;最后,计算其气动功率,研究能耗规律。结果表明:对柔性夹爪进行收缩实验时,给定的初始压力与柔性夹爪产生的压力相差不大,气动功率损耗较小;对柔性夹爪进行扩张实验时,提供的初始压力通过真空发生器间接作用在柔性夹爪上,与柔性夹爪产生的压力相差较大,柔性夹爪达到规定压力时需要提供更大的初始压力;柔性夹爪收缩时比扩张时的气动功率损耗低。

Abstract:The online measurement system of gas pressure, flow and other parameters was established to realize the regulation and control of the measurement and control system through the data acquisition system of industrial personal computer, combined with sensor technology, signal processing technology, etc. The pressure and flow rate of the flexible gripper under different initial pressures during contraction and expansion were collected respectively, then the pressure flow diagram of the flexible gripper was drawn by SigmaPlot, and the flow pressure output characteristics of the flexible gripper were analyzed. Finally, the pneumatic power was calculated to study the energy consumption law. The results show that through the contraction experiment of the flexible gripper, the difference between the given initial pressure and the pressure generated by the flexible gripper is small, and the loss of pneumatic power is relatively small. In the expansion experiment of the flexible gripper, because the initial pressure provided is indirectly acting on the flexible gripper through the vacuum generator, the difference between the pressure provided and the pressure generated by the flexible gripper is big. Larger initial pressure needs to be provided in order to make the flexible gripper reach the specified pressure. The pneumatic power loss of flexible gripper is lower during contraction than during expansion.

-

Key words:

- flexible gripper /

- data acquisition /

- pressure characteristic /

- flow characteristic /

- pneumatic power

-

表 1 主要元器件的型号和参数

Table 1. Models and parameters of main components

元器件 型号 参数 空气压缩机 PANDA 750-30L 最大供气压力:0.8 MPa 精密减压阀 IR2000-02B-R 最大工作压力:1.0 MPa 真空发生器 CV-10HS 压力范围:0.1~0.6 MPa 电磁换向阀 VT307-5G-01 量程:0~0.9 MPa 压力变送器 美控MIK-P300 量程:-0.1~0.1 MPa;精度:0.3%FS 流量计 FESTO SFAH-5U-Q6S-PNLK-PNVBA-M8 量程:0.1~5 L/min;精度:2% o.m.v.+1%FS 温度隔离器 顺来达SLDTR-2P11 响应时间:≤10 ms;精度:0.1%FS 数据采集卡 NI 6358 32位计数器;输出电压:-10~10 V 柔性夹爪 SFG-FMA 工作压力:-100~100 kPa;精度:0.08 mm 注:FS是Full-scale(满量程)的简写,表示满量程的线性(度), 即仪表显示的误差(整体误差); o.m.v.是Orifice Maximum Volume的英文简写,2% o.m.v.表示流量精度为孔口最大体积流量的2%。 -

[1] 曹玉君, 尚建忠, 梁科山, 等. 软体机器人研究现状综述[J]. 机械工程学报, 2012, 48(3): 25-33. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201203005.htmCAO Y J, SHANG J Z, LIANG K S, et al. Review of soft-bodied robots[J]. Journal of Mechanical Engineering, 2012, 48(3): 25-33(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201203005.htm [2] 张进华, 王韬, 洪军, 等. 软体机械手研究综述[J]. 机械工程学报, 2017, 53(13): 19-28. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201713003.htmZHANG J H, WANG T, HONG J, et al. Review of soft-bodied manipulator[J]. Journal of Mechanical Engineering, 2017, 53(13): 19-28(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201713003.htm [3] 张晗. 气动软体机械手抓取性能研究[D]. 西安: 西安理工大学, 2019: 1-8.ZHANG H. Research on grasping performance of pneumatic soft gripper[D]. Xi'an: Xi'an University of Technology, 2019: 1-8(in Chinese). [4] 韩鹰. 典型气动柔性执行器的设计建模与应用[D]. 哈尔滨: 哈尔滨工业大学, 2018: 5-11.HAN Y. Research on design modelling and application of typical pneumatic soft actuators[D]. Harbin: Harbin Institute of Technology, 2018: 5-11(in Chinese). [5] 钟佳炜, 刘忠, 霍佳波, 等. 比例压力流量阀控缸系统的建模与输出特性研究[J]. 机械制造与自动化, 2019, 48(4): 89-92. https://www.cnki.com.cn/Article/CJFDTOTAL-ZZHD201904024.htmZHONG J W, LIU Z, HUO J B, et al. Research on modeling and output characteristics of control cylinder system for proportional pressure flow valve[J]. Machine Building & Automation, 2019, 48(4): 89-92(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-ZZHD201904024.htm [6] 杨志春, 郁林聪. 单柱塞泵流量压力输出特性研究[J]. 液压与气动, 2019(10): 135-140. doi: 10.11832/j.issn.1000-4858.2019.10.023YANG Z C, YU L C. Study on flow and pressure characteristics of single piston pump[J]. Chinese Hydraulics & Pneumatics, 2019(10): 135-140(in Chinese). doi: 10.11832/j.issn.1000-4858.2019.10.023 [7] 蔡茂林, 石岩. 压缩空气系统节能关键技术体系及其应用[J]. 液压气动与密封, 2012, 32(12): 63-66. doi: 10.3969/j.issn.1008-0813.2012.12.021CAI M L, SHI Y. Energy-saving key technologies system of compressed air system and its applications[J]. Hydraulics Pneumatics & Seals, 2012, 32(12): 63-66(in Chinese). doi: 10.3969/j.issn.1008-0813.2012.12.021 [8] 刘永, 谷立臣, 杨彬, 等. 液压系统流量、压力闭环控制实验研究[J]. 机床与液压, 2017, 45(7): 23-25. doi: 10.3969/j.issn.1001-3881.2017.07.006LIU Y, GU L C, YANG B, et al. Experimental study on closed loop control of flow and pressure of hydraulic system[J]. Machine Tool & Hydraulics, 2017, 45(7): 23-25(in Chinese). doi: 10.3969/j.issn.1001-3881.2017.07.006 [9] 张晋涛, 杜玉红, 陈小龙, 等. 气体流量压力测试系统[J]. 机电工程技术, 2011, 40(10): 83-86. https://www.cnki.com.cn/Article/CJFDTOTAL-JXKF201110025.htmZHANG J T, DU Y H, CHEN X L, et al. Gas flow and pressure test system[J]. Electromechanical Engineering Technology, 2011, 40(10): 83-86(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXKF201110025.htm [10] 徐昆, 卢苇, 王博韬, 等. 气体在热流逸效应作用下的压力与流量特性[J]. 高校化学工程学报, 2017, 31(6): 1285-1292. doi: 10.3969/j.issn.1003-9015.2017.06.005XU K, LU W, WANG B T, et al. Pressure and mass flow characteristics of gases under thermal transpiration effects[J]. Journal of Chemical Engineering of Chinese Universities, 2017, 31(6): 1285-1292(in Chinese). doi: 10.3969/j.issn.1003-9015.2017.06.005 [11] 李珂. 摆动气缸位置伺服控制系统研究[D]. 焦作: 河南理工大学, 2019: 10-14.LI K. Research on pneumatic rotary actuator position servo control system[D]. Jiaozuo: Henan Polytechnic University, 2019: 10-14(in Chinese). [12] ZHANG Y M, YUE H W, LI K, et al. Analysis of power matching on energy saving of pneumatic rotary actuator servo-control system[J]. Chinese Journal of Mechanical Engineering, 2020(2): 87-99. http://www.cqvip.com/QK/85891X/202002/7101768404.html [13] ZHANG Y M, LI K, WANG G, et al. Nonlinear model establishment and experimental verification of a pneumatic rotary actuator position servo system[J]. Energies, 2019, 12(6): 1096. doi: 10.3390/en12061096 [14] CAI M L. Modern pneumatic technology theory and practice. Chapter 5: The characteristics of cylinder drive systems[J]. Hydraulics Pneumatics and Seals, 2007, 27(6): 55-58. [15] 蔡茂林, 香川利春. 气动系统的能量消耗评价体系及能量损失分析[J]. 机械工程学报, 2007, 43(9): 69-74. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200709017.htmCAI M L, KAGAWA T. Energy consumption assessment and energy loss analysis of pneumatic system[J]. Journal of Mechanical Engineering, 2007, 43(9): 69-74(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200709017.htm [16] ZHANG Y M, CAI M L. Overall life cycle comprehensive assessment of pneumatic and electric actuator[J]. Chinese Journal of Mechanical Engineering, 2014, 27(3): 584-594. doi: 10.3901/CJME.2014.03.584 -

下载:

下载: