-

摘要:

随着能源需求的日益高涨,锂离子电池(LIB)在各个领域内的应用愈发广泛。为满足极端气候等特殊应用环境对储能器件的需求,LIB需拓宽其工作温度范围。从材料和电池结构角度详细总结了应用于低温条件LIB的最新研究进展。首先,分析了限制LIB低温性能的根本原因;然后,分别从电解液的研发与优化、电极材料的改性和开发、新型电池体系的开发、电池热管理系统(BTMS)设计4个方面归纳并讨论了在低温情况下改善LIB性能的途径和方法;最后,总结了低温LIB研究亟待解决的问题,并为新一代低温LIB的发展提出了可行的研究方向。

-

关键词:

- 锂离子电池(LIB) /

- 低温性能 /

- 电解液 /

- 电极材料 /

- 电池热管理系统(BTMS)

Abstract:With the rising of energy requirements, Lithium-Ion Battery (LIB) have been widely used in various fields. To meet the requirement of stable operation of the energy-storage devices in extreme climate areas, LIB needs to further expand their working temperature range. In this paper, we comprehensively summarize the recent research progress of LIB at low temperature from the perspectives of material and the structural design of battery. First, the fundamental reasons of limiting low-temperature performance of LIB are analyzed. Then, the rational strategies for improving the low-temperature performance of LIB are discussed from four aspects: the research and optimization of electrolyte, the modification and exploitation of electrode materials, the development of new types of battery system as well as the design of Battery Thermal Management System (BTMS). Finally, the urgent problems to be solved in low-temperature LIB research are summarized, and the feasible research direction is suggested for the development of a new generation of low-temperature LIB.

-

-

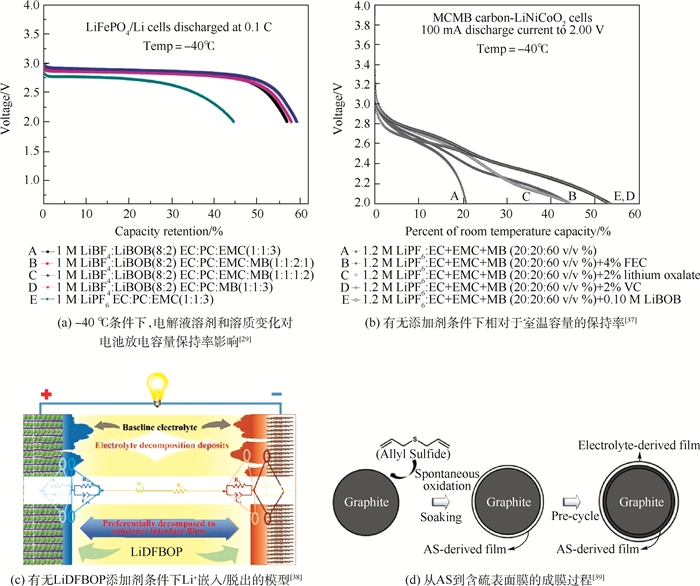

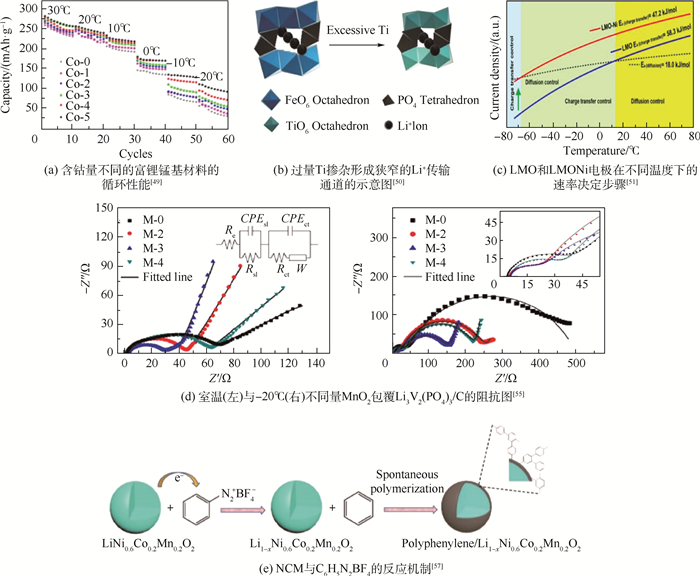

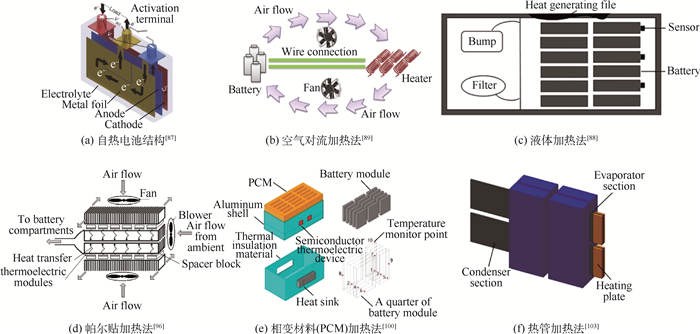

[1] RODRIGUES M T F, BABU G, GULLAPALLI H, et al. A materials perspective on Li-ion batteries at extreme temperatures[J]. Nature Energy, 2017, 2: 17108. doi: 10.1038/nenergy.2017.108 [2] 李瑛博, 韦韬. 临近太空飞行器及其军事应用[J]. 飞航导弹, 2011(9): 57-60.LI Y B, WEI T. Adjacent space aerocraft and their military applications[J]. Aerodynamic Missile Journal, 2011(9): 57-60(in Chinese). [3] 朱伟. "空中司令部"——近太空飞艇[J]. 国防, 2007(1): 81-82.ZHU W. "Air Command"-Near space airship[J]. National Defense, 2007(1): 81-82(in Chinese). [4] 操文祥, 张绍东, 易帆, 等. 中间层顶变化的SABER/TIMED卫星观测[J]. 地球物理学报, 2012, 55(8): 2489-2497.CAO W X, ZHANG S D, YI F, et al. Variation of the mesopause observed by SABER/TIMED satellite[J]. Chinese Journal of Geophysics, 2012, 55(8): 2489-2497(in Chinese). [5] LENG F, TAN C M, PECHT M. Effect of temperature on the aging rate of Li ion battery operating above room temperature[J]. Scientific Reports, 2015, 5: 12967. doi: 10.1038/srep12967 [6] 窦鹏, 袁中直. 北斗终端用宽温高比能电池的研发和应用[C]//第十一届中国卫星导航年会, 2020: 58-62.DOU P, YUAN Z Z. Research and development of wide temperature high energy density battery for Beidou terminal[C]//Proceedings of the 11th China Satellite Navigation Annual Conference, 2020: 58-62(in Chinese). [7] DONG X L, GUO Z W, GUO Z Y, et al. Organic batteries operated at -70℃[J]. Joule, 2018, 2(5): 902-913. doi: 10.1016/j.joule.2018.01.017 [8] THENUWARA A C, SHETTY P P, KONDEKAR N, et al. Efficient low-temperature cycling of lithium metal anodes by tailoring the solid-electrolyte interphase[J]. ACS Energy Letters, 2020, 5(7): 2411-2420. doi: 10.1021/acsenergylett.0c01209 [9] DONG X L, YANG Y, WANG B L, et al. Low-temperature charge/discharge of rechargeable battery realized by intercalation pseudocapacitive behavior[J]. Advanced Science, 2020, 7(14): 2000196. doi: 10.1002/advs.202000196 [10] FAN X L, JI X, CHEN L, et al. All-temperature batteries enabled by fluorinated electrolytes with non-polar solvents[J]. Nature Energy, 2019, 4(10): 882-890. doi: 10.1038/s41560-019-0474-3 [11] ZHU G L, WEN K C, LV W, et al. Materials insights into low-temperature performances of lithium-ion batteries[J]. Journal of Power Sources, 2015, 300: 29-40. doi: 10.1016/j.jpowsour.2015.09.056 [12] LI Q Y, JIAO S H, LUO L L, et al. Wide-temperature electrolytes for lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2017, 9(22): 18826-18835. [13] HOU J B, YANG M, WANG D Y, et al. Fundamentals and challenges of lithium ion batteries at temperatures between -40 and 60℃[J]. Advanced Energy Materials, 2020, 10(18): 2070079. doi: 10.1002/aenm.202070079 [14] 李继红, 何建新, 张先勇, 等. 某型军用锂离子电池低温环境适应性[J]. 装备环境工程, 2014, 11(1): 111-115.LI J H, HE J X, ZHANG X Y, et al. Environmental worthiness evaluation of a certain type of military lithium-ion battery at low temperature[J]. Equipment Environmental Engineering, 2014, 11(1): 111-115(in Chinese). [15] 胡悦丽, 许志, 陈立宝, 等. 导电剂及电解液对锂离子电池低温性能的影响[J]. 电源技术, 2013, 37(2): 204-208. doi: 10.3969/j.issn.1002-087X.2013.02.010HU Y L, XU Z, CHEN L B, et al. Effect of different conductive additives and electrolyte on low-temperature performance of Li-ion battery[J]. Chinese Journal of Power Sources, 2013, 37(2): 204-208(in Chinese). doi: 10.3969/j.issn.1002-087X.2013.02.010 [16] THENUWARA A C, SHETTY P P, MCDOWELL M T. Distinct nanoscale interphases and morphology of lithium metal electrodes operating at low temperatures[J]. Nano Letters, 2019, 19(12): 8664-8672. doi: 10.1021/acs.nanolett.9b03330 [17] 陈仕玉, 杨固长, 杨柳, 等. 低温型锂离子电池的研制[J]. 电源技术, 2019, 43(7): 1090-1093. doi: 10.3969/j.issn.1002-087X.2019.07.002CHEN S Y, YANG G C, YANG L, et al. Development of low temperature Li-ion batteries[J]. Chinese Journal of Power Sources, 2019, 43(7): 1090-1093(in Chinese). doi: 10.3969/j.issn.1002-087X.2019.07.002 [18] 顾月茹, 赵卫民, 苏长虎, 等. 锂离子电池低温性能改善研究进展[J]. 电化学, 2018, 24(5): 488-496.GU Y R, ZHAO W M, SU C H, et al. Research progresses in improvement for low temperature performance of lithium-ion batteries[J]. Journal of Electrochemistry, 2018, 24(5): 488-496(in Chinese). [19] PONROUCH A, MARCHANTE E, COURTY M, et al. In search of an optimized electrolyte for Na-ion batteries[J]. Energy & Environmental Science, 2012, 5(9): 8572-8583. [20] XU K. Nonaqueous liquid electrolytes for lithium-based rechargeable batteries[J]. Chemical Reviews, 2004, 104(10): 4303-4418. doi: 10.1021/cr030203g [21] XU K. Electrolytes and interphases in Li-ion batteries and beyond[J]. Chemical Reviews, 2014, 114(23): 11503-11618. doi: 10.1021/cr500003w [22] MANDAL B K, PADHI A K, SHI Z, et al. New low temperature electrolytes with thermal runaway inhibition for lithium-ion rechargeable batteries[J]. Journal of Power Sources, 2006, 162(1): 690-695. doi: 10.1016/j.jpowsour.2006.06.053 [23] SMART M C, RATNAKUMAR B V, WHITCANACK L D, et al. Improved low-temperature performance of lithium-ion cells with quaternary carbonate-based electrolytes[J]. Journal of Power Sources, 2003, 119: 349-358. [24] LIAO X Z, MA Z F, GONG Q, et al. Low-temperature performance of LiFePO4/C cathode in a quaternary carbonate-based electrolyte[J]. Electrochemistry Communications, 2008, 10(5): 691-694. doi: 10.1016/j.elecom.2008.02.017 [25] LU W, XIE K, PAN Y, et al. Effects of carbon-chain length of trifluoroacetate co-solvents for lithium-ion battery electrolytes using at low temperature[J]. Journal of Fluorine Chemistry, 2013, 156: 136-143. doi: 10.1016/j.jfluchem.2013.08.015 [26] LI J, YUAN C F, GUO Z H, et al. Limiting factors for low-temperature performance of electrolytes in LiFePO4/Li and graphite/Li half cells[J]. Electrochimica Acta, 2012, 59: 69-74. doi: 10.1016/j.electacta.2011.10.041 [27] LI Q Y, LU D P, ZHENG J M, et al. Li+ desolvation dictating lithium-ion battery's low-temperature performances[J]. ACS Applied Materials & Interfaces, 2017, 9(49): 42761-42768. [28] EIN-ELI Y, THOMAS S R, CHADHA R, et al. Li-ion battery electrolyte formulated for low-temperature applications[J]. Journal of the Electrochemical Society, 1997, 144(3): 823-829. doi: 10.1149/1.1837495 [29] LAI Y Q, PENG B, ZHANG Z A, et al. A wide operating temperature range electrolyte containing lithium salts mixture and a co-solvent for the LiFePO4 cathode[J]. Journal of the Electrochemical Society, 2014, 161(6): A875-A879. doi: 10.1149/2.023406jes [30] SMART M C, RATNAKUMAR B V, CHIN K B, et al. lithium-ion electrolytes containing ester cosolvents for improved low temperature performance[J]. Journal of the Electrochemical Society, 2010, 157(12): A1361-A1374. doi: 10.1149/1.3501236 [31] SMART M C, RATNAKUMAR B V, BEHAR A, et al. Gel polymer electrolyte lithium-ion cells with improved low temperature performance[J]. Journal of Power Sources, 2007, 165(2): 535-543. doi: 10.1016/j.jpowsour.2006.10.038 [32] DONG X L, LIN Y X, LI P L, et al. High-energy rechargeable metallic lithium battery at -70℃ enabled by a cosolvent electrolyte[J]. Angewandte Chemie International Edition, 2019, 58(17): 5623-5627. doi: 10.1002/anie.201900266 [33] HOLOUBEK J, YIN Y J, LI M Q, et al. Exploiting mechanistic solvation kinetics for dual-graphite batteries with high power output at extremely low temperature[J]. Angewandte Chemie International Edition, 2019, 58(52): 18892-18897. doi: 10.1002/anie.201912167 [34] XU J, WANG X, YUAN N Y, et al. Extending the low temperature operational limit of Li-ion battery to -80℃[J]. Energy Storage Materials, 2019, 23: 383-389. doi: 10.1016/j.ensm.2019.04.033 [35] WANG J Y, HUANG W, PEI A, et al. Improving cyclability of Li metal batteries at elevated temperatures and its origin revealed by cryo-electron microscopy[J]. Nature Energy, 2019, 4(8): 664-670. doi: 10.1038/s41560-019-0413-3 [36] 浦文婧, 芦伟, 谢凯, 等. 宽温型锂离子电池有机电解液的研究进展[J]. 材料导报, 2020, 34(7): 7036-7044.PU W J, LU W, XIE K, et al. Progress on the carbonate-based electrolyte designed for lithium-ion batteries with wide operating temperature range[J]. Materials Reports, 2020, 34(7): 7036-7044(in Chinese). [37] SMART M C, LUCHT B L, DALAVI S, et al. The effect of additives upon the performance of MCMB/LiNixCo1-xO2 Li-ion cells containing methyl butyrate-based wide operating temperature range electrolytes[J]. Journal of the Electrochemical Society, 2012, 159(6): A739-A751. doi: 10.1149/2.058206jes [38] LIAO B, LI H Y, XU M Q, et al. Designing low impedance interface films simultaneously on anode and cathode for high energy batteries[J]. Advanced Energy Materials, 2018, 8(22): 1800802. doi: 10.1002/aenm.201800802 [39] JURNG S, PARK S, YOON T, et al. Low-temperature performance improvement of graphite electrode by allyl sulfide additive and its film-forming mechanism[J]. Journal of the Electrochemical Society, 2016, 163(8): A1798-A1804. doi: 10.1149/2.0051609jes [40] 鲍恺婧, 蔡亚果, 朴贤卿. 低温锂离子电池的研究进展[J]. 电池, 2019, 49(5): 435-439.BAO K J, CAI Y G, PIAO X Q. Research progress in low temperature Li-ion battery[J]. Battery Bimonthly, 2019, 49(5): 435-439(in Chinese). [41] RUSTOMJI C S, YANG Y, KIM T K, et al. Liquefied gas electrolytes for electrochemical energy storage devices[J]. Science, 2017, 356(6345): 1351. [42] YANG Y, DAVIES D M, YIN Y J, et al. High-efficiency lithium-metal anode enabled by liquefied gas electrolytes[J]. Joule, 2019, 3(8): 1986-2000. doi: 10.1016/j.joule.2019.06.008 [43] YANG Y, YIN Y J, DAVIES D M, et al. Liquefied gas electrolytes for wide-temperature lithium metal batteries[J]. Energy & Environmental Science, 2020, 13(7): 2209-2219. [44] HOLOUBEK J, YU M Y, YU S C, et al. An all-fluorinated ester electrolyte for stable high-voltage Li metal batteries capable of ultra-low-temperature operation[J]. ACS Energy Letters, 2020, 5(5): 1438-1447. doi: 10.1021/acsenergylett.0c00643 [45] LI X W, ZHENG Y W, LI C Y. Dendrite-free, wide temperature range lithium metal batteries enabled by hybrid network ionic liquids[J]. Energy Storage Materials, 2020, 29: 273-280. doi: 10.1016/j.ensm.2020.04.037 [46] HAN F D, WESTOVER A S, YUE J, et al. High electronic conductivity as the origin of lithium dendrite formation within solid electrolytes[J]. Nature Energy, 2019, 4(3): 187-196. doi: 10.1038/s41560-018-0312-z [47] LV D, WANG L, HU P F, et al. Li2O-B2O3-Li2SO4 modified LiNi1/3Co1/3Mn1/3O2 cathode material for enhanced electrochemical performance[J]. Electrochimica Acta, 2017, 247: 803-811. doi: 10.1016/j.electacta.2017.07.068 [48] 李之锋, 罗垂意, 王春香, 等. 无钴镍基正极材料LiNi0.7Mn0.3O2氟掺杂改性研究[J]. 材料导报, 2018, 32(14): 2329-2334. doi: 10.11896/j.issn.1005-023X.2018.14.001LI Z F, LUO C Y, WANG C X, et al. Synthesis and property of F-doped LiNi0.7Mn0.3O2 cobalt-free nickel-rich cathode material for Li-ion battery[J]. Materials Report, 2018, 32(14): 2329-2334(in Chinese). doi: 10.11896/j.issn.1005-023X.2018.14.001 [49] KOU J W, CHEN L, SU Y F, et al. Role of cobalt content in improving the low-temperature performance of layered lithium-rich cathode materials for lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2015, 7(32): 17910-17918. [50] LI Z F, REN X, ZHENG Y, et al. Effect of Ti doping on LiFePO4/C cathode material with enhanced low-temperature electrochemical performance[J]. Ionics, 2020, 26(4): 1599-1609. doi: 10.1007/s11581-019-03408-4 [51] ZHANG W, SUN X L, TANG Y X, et al. Lowering charge transfer barrier of LiMn2O4 via nickel surface doping to enhance Li+ intercalation kinetics at subzero temperatures[J]. Journal of the American Chemical Society, 2019, 141(36): 14038-14042. doi: 10.1021/jacs.9b05531 [52] 李向南, 张会双, 曹朝霞, 等. 稀土离子掺杂合成LiFePO4/C材料低温性能研究[J]. 电源技术, 2016, 40(6): 1163-1166. doi: 10.3969/j.issn.1002-087X.2016.06.002LI X N, ZHANG H S, CAO Z X, et al. Low temperature performance of LiFePO4/C material doped by rare-earth ion[J]. Chinese Journal of Power Sources, 2016, 40(6): 1163-1166(in Chinese). doi: 10.3969/j.issn.1002-087X.2016.06.002 [53] LV Y J, HUANG B, TAN J X, et al. Enhanced low temperature electrochemical performances of LiFePO4/C by V3+ and F- co-doping[J]. Materials Letters, 2018, 229: 349-352. doi: 10.1016/j.matlet.2018.07.049 [54] ZHANG B F, XU Y L, WANG J, et al. Lanthanum and cerium Co-doped LiFePO4: Morphology, electrochemical performance and kinetic study from -30-+50℃[J]. Electrochimica Acta, 2019, 332: 134686. [55] 孙丹丹. MnO2纳米包覆改性Li3V2(PO4)3/C正极材料的制备及电化学性能的研究[D]. 天津: 天津大学, 2017.SUN D D. Preparation and electrochemical properties of MnO2 coated Li3V2(PO4)3/C cathode materials[D]. Tianjin: Tianjin University, 2017(in Chinese). [56] 谢坤池. 正极材料Li3V2(PO4)3改性制备及其低温性能研究[J]. 分子科学学报, 2019, 35(2): 121-127.XIE K C. Preparation and low temperature electrochemical performance of Li3V2(PO4)3 cathode[J]. Journal of Molecular Science, 2019, 35(2): 121-127(in Chinese). [57] SUN Z H, LI Z, GAO L F, et al. Grafting benzenediazonium tetrafluoroborate onto LiNixCoyMnzO2 materials achieves subzero-temperature high-capacity lithium-ion storage via a diazonium soft-chemistry method[J]. Advanced Energy Materials, 2019, 9(6): 1802946. doi: 10.1002/aenm.201802946 [58] HU Q, LIAO J Y, ZOU B K, et al. Improving the rate and low-temperature performance of LiFePO4 by tailoring the form of carbon coating from amorphous to graphene-like[J]. Journal of Solid State Electrochemistry, 2018, 22(3): 797-805. doi: 10.1007/s10008-017-3777-y [59] 江虹, 徐江海, 郭瑞松, 等. CeO2与碳共包覆Li3V2(PO4)3正极材料低温电化学性能[J]. 硅酸盐学报, 2016, 44(1): 6-12.JIANG H, XU J H, GUO R S, et al. Low-temperature electrochemical properties of CeO2 and carbon co-coated Li3V2(PO4)3 cathode materials[J]. Journal of the Chinese Ceramic Society, 2016, 44(1): 6-12(in Chinese). [60] YANG W C, BI Y J, QIN Y P, et al. LiMn0.8Fe0.2PO4/C cathode material synthesized via co-precipitation method with superior high-rate and low-temperature performances for lithium-ion batteries[J]. Journal of Power Sources, 2015, 275: 785-791. doi: 10.1016/j.jpowsour.2014.11.063 [61] ZHAO N N, LI Y S, ZHAO X X, et al. Effect of particle size and purity on the low temperature electrochemical performance of LiFePO4/C cathode material[J]. Journal of Alloys and Compounds, 2016, 683: 123-132. doi: 10.1016/j.jallcom.2016.04.070 [62] WANG Y, DENG Y H, QU Q T, et al. Ultrahigh-capacity organic anode with high-rate capability and long cycle life for lithium-ion batteries[J]. ACS Energy Letters, 2017, 2(9): 2140-2148. doi: 10.1021/acsenergylett.7b00622 [63] LI C, NAKAMURA M, INAYAMA S, et al. Alkali metal ion storage of quinone molecules grafted on single-walled carbon nanotubes at low temperature[J]. ACS Omega, 2018, 3(11): 15598-15605. doi: 10.1021/acsomega.8b02844 [64] PETZL M, KASPER M, DANZER M A. Lithium plating in a commercial lithiumion battery-A low-temperature aging study[J]. Journal of Power Sources, 2015, 275: 799-807. doi: 10.1016/j.jpowsour.2014.11.065 [65] 李典. 温度对锂负极沉积行为影响的研究[D]. 武汉: 华中科技大学, 2019.LI D. Investigation of the temperature effects on the deposition behaviors of lithium anode[D]. Wuhan: Huazhong University of Science and Technology, 2019(in Chinese). [66] YAN K, WANG J Y, ZHAO S Q, et al. Temperature-dependent nucleation and growth of dendrite-free lithium metal anodes[J]. Angewandte Chemie International Edition, 2019, 58(33): 11364-11368. doi: 10.1002/anie.201905251 [67] VON LUDERS C, ZINTH V, ERHARD S V, et al. Lithium plating in lithium-ion batteries investigated by voltage relaxation and in situ neutron diffraction[J]. Journal of Power Sources, 2017, 342: 17-23. doi: 10.1016/j.jpowsour.2016.12.032 [68] WANG H, YU D D, KUANG C W, et al. Alkali metal anodes for rechargeable batteries[J]. Chem, 2019, 5(2): 313-338. doi: 10.1016/j.chempr.2018.11.005 [69] WEBER R, GENOVESE M, LOULI A J, et al. Long cycle life and dendrite-free lithium morphology in anode-free lithium pouch cells enabled by a dual-salt liquid electrolyte[J]. Nature Energy, 2019, 4(8): 683-689. doi: 10.1038/s41560-019-0428-9 [70] GAO Y, ROJAS T, WANG K, et al. Low-temperature and high-rate-charging lithium metal batteries enabled by an electrochemically active monolayer-regulated interface[J]. Nature Energy, 2020, 5(7): 534-542. doi: 10.1038/s41560-020-0640-7 [71] CHEN S J, XIANG Y X, ZHENG G R, et al. High-efficiency lithium metal anode enabled by a concentrated/fluorinated ester electrolyte[J]. ACS Applied Materials and Interfaces, 2020, 12(24): 27794-27802. doi: 10.1021/acsami.0c06930 [72] 谢晓华, 解晶莹, 夏保佳. 锂离子电池低温充放电性能的研究[J]. 化学世界, 2008, 49(10): 581-583. doi: 10.3969/j.issn.0367-6358.2008.10.002XIE X H, XIE J Y, XIA B J. Study on the charge and discharge performance of lithium ion batteries at low temperature[J]. Chemical World, 2008, 49(10): 581-583(in Chinese). doi: 10.3969/j.issn.0367-6358.2008.10.002 [73] 冯祥明, 张晶晶, 李荣富, 等. LiFePO4锂离子电池的低温性能[J]. 电池, 2009, 39(1): 36-37. doi: 10.3969/j.issn.1001-1579.2009.01.013FENG X M, ZHANG J J, LI R F, et al. Low temperature performance of LiFePO4 Li-ion battery[J]. Battery Bimonthly, 2009, 39(1): 36-37(in Chinese). doi: 10.3969/j.issn.1001-1579.2009.01.013 [74] ZHANG S S, XU K, JOW T R. Electrochemical impedance study on the low temperature of Li-ion batteries[J]. Electrochimica Acta, 2004, 49(7): 1057-1061. doi: 10.1016/j.electacta.2003.10.016 [75] HOU B H, WANG Y Y, NING Q L, et al. Self-supporting, flexible, additive-free, and scalable hard carbon paper self-interwoven by 1D microbelts: Superb room/low-temperature sodium storage and working mechanism[J]. Advanced Materials, 2019, 31(40): 1903125. doi: 10.1002/adma.201903125 [76] HUANG C K, SAKAMOTO J S, WOLFENSTINE J, et al. The limits of low-temperature performance of Li-ion cells[J]. Journal of the Electrochemical Society, 2000, 147(8): 2893-2896. doi: 10.1149/1.1393622 [77] SIDES C R, MARTIN C R. Nanostructured electrodes and the low-temperature performance of Li-ion batteries[J]. Advanced Materials, 2005, 17(1): 125-128. doi: 10.1002/adma.200400517 [78] LI J R, TANG Z L, ZHANG Z T. Excellent low-temperature lithium intercalation performance of nanostructured hydrogen titanate electrodes[J]. Electrochemical and Solid-State Letters, 2005, 8(11): A570-A573. doi: 10.1149/1.2039960 [79] 马少宁, 侯春平, 贺超, 等. 煤基软炭锂离子电池负极材料的低温性能研究[J]. 炭素技术, 2016, 35(3): 47-50.MA S N, HOU C P, HE C, et al. The low-temperature performance of coal-based soft carbon anode material for Li-ion batteries[J]. Carbon Techniques, 2016, 35(3): 47-50(in Chinese). [80] 林浩, 张洪信, 徐方超. 软碳电池储能电站低温特性研究[J]. 电源技术, 2019, 43(11): 1782-1784.LIN H, ZHANG H X, XU F C. Study on low temperature characteristics of soft carbon batteries for energy storage power plant[J]. Chinese Journal of Power Sources, 2019, 43(11): 1782-1784(in Chinese). [81] 刘萍, 高飞, 张娜, 等. 软碳掺杂对大容量锂离子电池低温性能的影响[J]. 电源技术, 2017, 41(8): 1112-1113. doi: 10.3969/j.issn.1002-087X.2017.08.002LIU P, GAO F, ZHANG N, et al. Effects of soft carbon doping on low temperature performance of large capacity LiFePO4 batteries[J]. Chinese Journal of Power Sources, 2017, 41(8): 1112-1113(in Chinese). doi: 10.3969/j.issn.1002-087X.2017.08.002 [82] 田小东. 锂离子电池负极锰氧化物复合材料的制备及其电化学性能研究[D]. 广州: 华南理工大学, 2018.TIAN X D. Preparation and electrochemical performance research of manganese oxides as anode materials for lithium-ion batteries[D]. Guangzhou: South China University of Technology, 2018(in Chinese). [83] 赵世玺, 郭双桃, 赵建伟, 等. 锂离子电池低温特性研究进展[J]. 硅酸盐学报, 2016, 44(1): 25-34.ZHAO S X, GUO S T, ZHAO J W, et al. Development on low-temperature performance of lithium ion batteries[J]. Journal of the Chinese Ceramic Society, 2016, 44(1): 25-34(in Chinese). [84] YUAN T, YU X, CAI R, et al. Synthesis of pristine and carbon-coated Li4Ti5O12 and their low-temperature electrochemical performance[J]. Journal of Power Sources, 2010, 195(15): 4997-5004. doi: 10.1016/j.jpowsour.2010.02.020 [85] NOBILI F, MANCINI M, DSOKE S, et al. Low-temperature behavior of graphite-tin composite anodes for Li-ion batteries[J]. Journal of Power Sources, 2010, 195(20): 7090-7097. doi: 10.1016/j.jpowsour.2010.05.001 [86] 何理. 锂离子电池纳米ZnS/C负极材料制备及性能[D]. 上海: 上海交通大学, 2011.HE L. Studies on nano ZnS/C composite as anode materials for lithium-ion batteries[D]. Shanghai: Shanghai Jiaotong University, 2011(in Chinese). [87] 刘建文, 常赟. 钛酸锂材料蓄电池低温性能[J]. 电源技术, 2013, 37(9): 1524-1526. doi: 10.3969/j.issn.1002-087X.2013.09.009LIU J W, CHANG Y. Research of low-temperature performance of Li4Ti5O12 material battery[J]. Chinese Journal of Power Sources, 2013, 37(9): 1524-1526(in Chinese). doi: 10.3969/j.issn.1002-087X.2013.09.009 [88] ZHU F L, BAO H F, WU X S, et al. High-performance metal-organic framework-based single ion conducting solid-state electrolytes for low-temperature lithium metal batteries[J]. ACS Applied Materials & Interfaces, 2019, 11(46): 43206-43213. [89] LIN Z H, LIU J. Low-temperature all-solid-state lithium-ion batteries based on a di-cross-linked starch solid electrolyte[J]. RSC Advances, 2019, 9(59): 34601-34606. doi: 10.1039/C9RA07781B [90] TRON A, JEONG S, PARK Y D, et al. Aqueous lithium-ion battery of nano-LiFePO4 with antifreezing agent of ethyleneglycol for low-temperature operation[J]. ACS Sustainable Chemistry and Engineering, 2019, 7(17): 14531-14538. doi: 10.1021/acssuschemeng.9b02042 [91] WANG H Q, ZHANG H Z, CHENG Y, et al. All-NASICON LVP-LTP aqueous lithium ion battery with excellent stability and low-temperature performance[J]. Electrochimica Acta, 2018, 278: 279-289. doi: 10.1016/j.electacta.2018.05.047 [92] MA X H, WEI Y Y, WU Y D, et al. High crystalline Na2Ni[Fe(CN)6] particles for a high-stability and low-temperature sodium-ion batteries cathode[J]. Electrochimica Acta, 2019, 297: 392-397. doi: 10.1016/j.electacta.2018.11.063 [93] BAI Z Y, LV X, LIU D H, et al. Cover feature: Two-dimensional NiO@C-N nanosheets composite as a superior low-temperature anode material for advanced lithium-/sodium -ion batteries[J]. ChemElectroChem, 2020, 7(17): 3542. doi: 10.1002/celc.202000985 [94] WANG L, WANG B, LIU G J, et al. Carbon nanotube decorated NaTi2(PO4)3/C nanocomposite for a high-rate and low-temperature sodium-ion battery anode[J]. RSC Advances, 2016, 6(74): 70277-70283. doi: 10.1039/C6RA11042H [95] GUO J Z, WANG P F, WU X L, et al. High-energy/power and low-temperature cathode for sodium-ion batteries: In situ XRD study and superior full-cell performance[J]. Advanced Materials, 2017, 29(33): 1701968. doi: 10.1002/adma.201701968 [96] WANG Y Y, HOU B H, GUO J Z, et al. An ultralong lifespan and low-temperature workable sodium-ion full battery for stationary energy storage[J]. Advanced Energy Materials, 2018, 8(18): 1703252. doi: 10.1002/aenm.201703252 [97] HOU B H, WANG Y Y, LIU D S, et al. N-doped carbon-coated Ni1.8Co1.2Se4 nanoaggregates encapsulated in N-doped carbon nanoboxes as advanced anode with outstanding high-rate and low-temperature performance for sodium-ion half/full batteries[J]. Advanced Functional Materials, 2018, 28(47): 1805444. doi: 10.1002/adfm.201805444 [98] STUART T A, HANDE A. HEV battery heating using AC currents[J]. Journal of Power Sources, 2004, 129(2): 368-378. doi: 10.1016/j.jpowsour.2003.10.014 [99] ZHANG J B, GE H, LI Z, et al. Internal heating of lithium-ion batteries using alternating current based on the heat generation model in frequency domain[J]. Journal of Power Sources, 2015, 273: 1030-1037. doi: 10.1016/j.jpowsour.2014.09.181 [100] GE H, HUANG J, ZHANG J B, et al. Temperature-adaptive alternating current preheating of lithium-ion batteries with lithium deposition prevention[J]. Journal of the Electrochemical Society, 2016, 163(2): A290-A299. doi: 10.1149/2.0961602jes [101] WANG C Y, ZHANG G S, GE S H, et al. Lithium-ion battery structure that self-heats at low temperatures[J]. Nature, 2016, 529(7587): 515-518. doi: 10.1038/nature16502 [102] ZHANG G S, GE S H, XU T, et al. Rapid self-heating and internal temperature sensing of lithium-ion batteries at low temperatures[J]. Electrochimica Acta, 2016, 218: 149-155. doi: 10.1016/j.electacta.2016.09.117 [103] PENG X B, CHEN S Q, GARG A, et al. A review of the estimation and heating methods for lithium-ion batteries pack at the cold environment[J]. Energy Science & Engineering, 2019, 7(3): 645-662. [104] JI Y, WANG C Y. Heating strategies for Li-ion batteries operated from subzero temperatures[J]. Electrochimica Acta, 2013, 107: 664-674. doi: 10.1016/j.electacta.2013.03.147 [105] RAO Z H, WANG S F, ZHANG Y L. Thermal management with phase change material for a power battery under cold temperatures[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2014, 36(20): 2287-2295. doi: 10.1080/15567036.2011.576411 [106] BABAPOOR A, AZIZI M, KARIMI G. Thermal management of a Li-ion battery using carbon fiber-PCM composites[J]. Applied Thermal Engineering, 2015, 82: 281-290. doi: 10.1016/j.applthermaleng.2015.02.068 [107] TROXLER Y, WU B, MARINESCU M, et al. The effect of thermal gradients on the performance of lithium-ion batteries[J]. Journal of Power Sources, 2014, 247: 1018-1025. doi: 10.1016/j.jpowsour.2013.06.084 [108] 王发成, 张俊智, 王丽芳. 车载动力电池组用空气电加热装置设计[J]. 电源技术, 2013, 37(7): 1184-1187. doi: 10.3969/j.issn.1002-087X.2013.07.030WANG F C, ZHANG J Z, WANG L F. Design of electric air-heated box for batteries in electric vehicles[J]. Chinese Journal of Power Sources, 2013, 37(7): 1184-1187(in Chinese). doi: 10.3969/j.issn.1002-087X.2013.07.030 [109] 王发成, 李春明, 郭强, 等. 动力电池组用空气自加热装置试验研究[J]. 电源技术, 2020, 44(7): 961-963. doi: 10.3969/j.issn.1002-087X.2020.07.008WANG F C, LI C M, GUO Q, et al. Test of air self-heating device for power batteries[J]. Chinese Journal of Power Sources, 2020, 44(7): 961-963(in Chinese). doi: 10.3969/j.issn.1002-087X.2020.07.008 [110] ZHANG S S, XU K, JOW T R. A new approach toward improved low temperature performance of Li-ion battery[J]. Electrochemistry Communications, 2002, 4(11): 928-932. doi: 10.1016/S1388-2481(02)00490-3 [111] ALAOUI C, SALAMEH Z M. A novel thermal management for electric and hybrid vehicles[J]. IEEE Transactions on Vehicular Technology, 2005, 54(2): 468-476. doi: 10.1109/TVT.2004.842444 [112] HALLAJ S A, SELMAN J R. A novel thermal management system for electric vehicle batteries using phase-change material[J]. Journal of the Electrochemical Society, 2000, 147(9): 3231-3236. doi: 10.1149/1.1393888 [113] HUO Y T, RAO Z H. Investigation of phase change material based battery thermal management at cold temperature using lattice Boltzmann method[J]. Energy Conversion and Management, 2017, 133: 204-215. doi: 10.1016/j.enconman.2016.12.009 [114] LING Z Y, WEN X Y, ZHANG Z G, et al. Thermal management performance of phase change materials with different thermal conductivities for Li-ion battery packs operated at low temperatures[J]. Energy, 2018, 144: 977-983. doi: 10.1016/j.energy.2017.12.098 [115] SONG W J, BAI F F, CHEN M B, et al. Thermal management of standby battery for outdoor base station based on the semiconductor thermoelectric device and phase change materials[J]. Applied Thermal Engineering, 2018, 137: 203-217. doi: 10.1016/j.applthermaleng.2018.03.072 [116] WANG Q, JIANG B, XUE Q F, et al. Experimental investigation on EV battery cooling and heating by heat pipes[J]. Applied Thermal Engineering, 2015, 88: 54-60. doi: 10.1016/j.applthermaleng.2014.09.083 [117] 叶欣, 赵耀华, 全贞花. 电动汽车锂离子电池散热加热设计[J]. 北京工业大学学报, 2017, 43(8): 1263-1267.YE X, ZHAO Y H, QUAN Z H. Design of cooling and heating of lithium-ion battery used in electric vehicle[J]. Journal of Beijing University of Technology, 2017, 43(8): 1263-1267(in Chinese). [118] YE X, ZHAO Y H, QUAN Z H. Thermal management system of lithium-ion battery module based on micro heat pipe array[J]. International Journal of Energy Research, 2018, 42(2): 648-655. doi: 10.1002/er.3847 期刊类型引用(1)

1. 尚涛,孙海正,刘建伟. 基于斐波那契编码的测量设备无关量子密钥分发方案. 航空科学技术. 2021(03): 71-78 .  百度学术

百度学术其他类型引用(2)

-

下载:

下载:

百度学术

百度学术