Effects of prepreg ambient-temperature storage life on mechanical properties of MT700/603 composites

-

摘要:

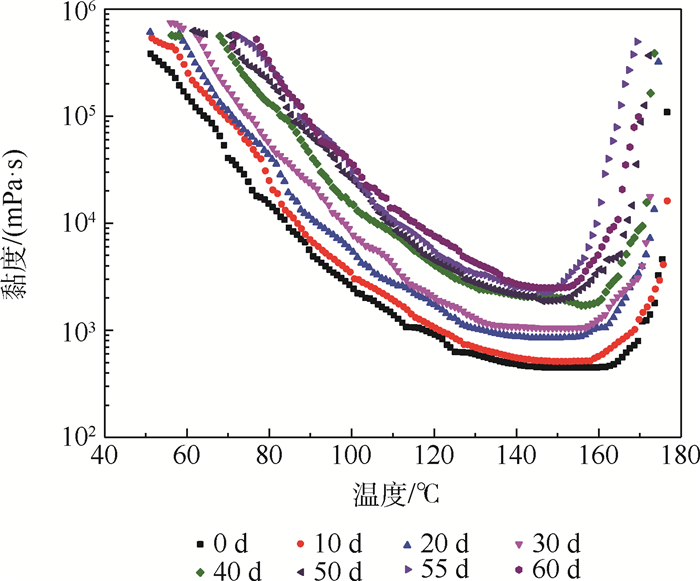

以碳纤维增强环氧树脂热熔预浸料MT700/603为研究对象,开展室温贮存时间与预固化度的关联性分析,研究预浸料预固化度对复合材料成型质量和关键力学性能的影响机制,建立预浸料贮存时间-预固化度-制品性能三者之间的内在联系。结果表明:随着室温贮存时间的延长,60 d后603环氧树脂的最低黏度增加了4.6倍,玻璃化转变温度增加了17.9 ℃,预固化度为11.2%;MT700/603预浸料贮存时间小于30 d时,制备的复合材料内部质量良好,纤维分布较为均匀,孔隙率较低,树脂的预固化度在5.3%以内,孔隙率低于0.03%;复合材料更倾向依赖于树脂基体破坏的纵向压缩强度和压缩模量对孔隙率的敏感度,要高于倾向依赖于纤维增强体破坏的纵向拉伸强度和拉伸模量;预浸料在室温贮存时树脂预固化度增加,黏度增大,加压时机与树脂黏度变化不匹配是导致复合材料构件关键力学性能下降的根本原因;根据产品的力学性能指标要求,结合不同贮存时间的关键力学性能数据,可反推出预浸料的最长室温贮存时间,实现了预浸料可用性的定量化评估。

Abstract:A hot-melt prepreg MT700/603 was prepared. The correlation between ambient-temperature storage life and the degree of pre-curing, and effects of pre-curing degree on composite quality and mechanical properties were investigated and discussed. The relationship among prepreg storage life, pre-curing degree and composite properties was established. The results show that the minimum viscosity is increased by 4.6 times after 60 days' storage at room temperature. Meanwhile, the glass transition temperature is increased by 17.9 ℃ and the pre-curing degree is increased to 11.2%. When storage life is less than 30 days, the composites show good internal quality, uniform fiber distribution and low porosity (≤0.03%), and the pre-curing degree is less than 5.3%. The longitudinal compression strength and modulus of composites tendentiously dependent on the failure of resin matrix are more sensitive to porosity than the longitudinal tensile strength and modulus dependent on the failure of fiber reinforcement. With the extension of storage life, the pre-curing degree and the viscosity of resin increases, and there is a mismatch between the pressurized moment and the resin gel point, which is the fundamental reason for the decrease of mechanical properties in composites. The maximum ambient-temperature storage life can be deduced according to the design requirement and mechanical properties data in different storage periods, realizing the quantitative evaluation of the prepreg availability.

-

-

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1): 1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU S Y. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica, 2007, 24(1): 1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] WIGGRES H, FERRO O, SALES R C M, et al. Comparison between the mechanical properties of carbon/epoxy laminates manufactured by autoclave and pressurized prepreg[J]. Polymer Composites, 2018, 39(S4): 2562-2572. doi: 10.1002/pc.24842 [3] JONES R W, NG Y, MCCLELLAND J F. Monitoring ambient-temperature aging of a carbon-fiber/epoxy composite prepreg with photoacoustic spectroscopy[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(6): 965-971. doi: 10.1016/j.compositesa.2008.03.015 [4] 王斌, 杨建奎, 方东红, 等. 湿法缠绕用环氧配方适用期研究[J]. 固体火箭技术, 1999, 22(4): 61-64. https://www.cnki.com.cn/Article/CJFDTOTAL-GTHJ199904016.htmWANG B, YANG J K, FANG D H, et al. Pot life of epoxy formula for wet winding[J]. Journal of Solid Rocket Technology, 1999, 22(4): 61-64(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-GTHJ199904016.htm [5] 郭战胜, 杜善义, 张博明, 等. 先进复合材料用环氧树脂的固化反应和化学流变[J]. 复合材料学报, 2004, 21(4): 146-151. doi: 10.13801/j.cnki.fhclxb.2004.04.029GUO Z S, DU S Y, ZAHNG B M, et al. Cure kinetics and chemorheological behavior of epoxy resin used in advanced composites[J]. Acta Materiae Compositae Sinica, 2004, 21(4): 146-151(in Chinese). doi: 10.13801/j.cnki.fhclxb.2004.04.029 [6] KIM D, CENTEA T, NUTT S R. In-situ cure monitoring of an out-of-autoclave prepreg: Effects of out-time on viscosity, gelation and vitrification[J]. Composites Science and Technology, 2014, 102: 132-138. doi: 10.1016/j.compscitech.2014.07.027 [7] CHAMBERS A R, EARL J S, SQUIRES C A, et al. The effects of voids on the flexural fatigue performance of unidirectional carbon fibre composites developed for wind turbine applications[J]. International Journal of Fatigue, 2006, 28(10): 1389-1398. doi: 10.1016/j.ijfatigue.2006.02.033 [8] PARK S Y, CHOI W J, CHOI H S. The effects of voids contents on the long-term hygrothermal behaviors of glass/epoxy and GLARE laminates[J]. Composites Structures, 2010, 92: 18-24. doi: 10.1016/j.compstruct.2009.06.006 [9] ALMEIDA S F M, NETO Z S N. Effects of voids contents on the strength of composite laminates[J]. Composites Structures, 1994, 8: 139-148. [10] 沈超. 3232树脂预浸料的贮存试验研究[J]. 航空材料学报, 2003, 23(SI): 168-170. https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB2003S1037.htmSHEN C. Investigations on the storage of 3232 resin prepreg[J]. Journal of Aeronautical Materials, 2003, 23(SI): 168-170(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB2003S1037.htm [11] 臧千, 樊孟金, 白雪莲, 等. 603树脂体系及其热熔预浸料室温储存期性能研究[J]. 固体火箭技术, 2018, 41(3): 383-387. https://www.cnki.com.cn/Article/CJFDTOTAL-GTHJ201803020.htmZANG Q, FAN M J, BAI X L, et al. Study of properties of 603 epoxy resin and its prepreg during storage at room temperature[J]. Journal of Solid Rocket Technology, 2018, 41(3): 383-387(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-GTHJ201803020.htm [12] 秦永乐, 孟江燕, 李伟东, 等. 碳纤维增强双马来酰亚胺树脂预浸料铺覆黏性及其储存老化行为[J]. 复合材料学报, 2019, 36(8): 1830-1837. https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201908006.htmQIN Y L, MENG J Y, LI W D, et al. Placement tack and storage aging behavior and carbon fiber reinforced bismaleimide prepreg[J]. Acta Materiae Compositae Sinica, 2019, 36(8): 1830-1837(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201908006.htm [13] GRUNENFELDER L K, CENTEA T, HUBERT P, et al. Effect of room-temperature out-time on tow impregnation in an out-of-autoclave prepreg[J]. Composites Part A: Applied Science and Manufacturing, 2013, 45: 119-126. doi: 10.1016/j.compositesa.2012.10.001 [14] 刘玲, 路明坤, 张博明, 等. 孔隙率对碳纤维复合材料超声衰减系数和力学性能的影响[J]. 复合材料学报, 2004, 21(5): 116-121. https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE200405022.htmLIU L, LU M K, ZAHNG B M, et al. Effects of porosity on the ultrasonic absorption coefficient and mechanical strength of carbon/epoxy composites[J]. Acta Materiae Compositae Sinica, 2004, 21(5): 116-121(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE200405022.htm [15] 刘玲, 张博明, 王殿富, 等. 聚合物基复合材料中孔隙率及层间剪切性能的试验表征[J]. 航空材料学报, 2006, 26(4): 115-118. https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB200604025.htmLIU L, ZAHNG B M, WANG D F, et al. Experimental characterization of porosity and interlaminar shear strength in polymeric matric composites[J]. Journal of Aeronautical Materials, 2006, 26(4): 115-118(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB200604025.htm [16] 刘志真, 李宏运, 益小苏. 孔隙率对聚酰亚胺复合材料力学性能的影响[J]. 材料工程, 2005(9): 56-58. https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC200509014.htmLIU Z Z, LI H Y, YI X S. Influence of void content on mechanical properties of polyimide composite[J]. Journal of Materials Engineering, 2005(9): 56-58(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC200509014.htm [17] 张冬梅, 叶金蕊, 刘奎, 等. 孔隙微观特征影响CFRP力学性能的细观综述[J]. 复合材料学报, 2013, 30(增刊): 118-123. https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE2013S1024.htmZHANG D M, YE J R, LIU K, et al. Effects of void micro-characteristics on the mechanical behavior of CFRP by micromechanical method[J]. Acta Materias Compositae Sinica, 2013, 30(Suppl): 118-123(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE2013S1024.htm [18] OLIVIER P, COTTU J P, FERRET B. Effects of cure cycle pressure and voids on some mechanical properties of carbon/epoxy laminates[J]. Composites, 1995, 26(7): 509-515. [19] CINQUIN J, TRIQUENAUX V, ROUSNE Y. Porosity influence on organic composite material mechanical properties[C]//16th International Conference on Composite Materials, 2007: 1-8. [20] TUDD N C W, WRIGHT W W. Voids and their effects on the mechanical properties of composites-An appraisal[J]. Sampe Journal, 1978, 14: 10-14. [21] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 纤维增强塑料密度和相对密度试验方法: GB/T 1463—2005[S]. 北京: 中国标准出版社, 2005.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration. Test methods for density and relative density of fiber reinforced plastics: GB/T 1463—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [22] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 碳纤维增强塑料孔隙含量和纤维体积含量试验方法: GB/T 3365—2008[S]. 北京: 中国标准出版社, 2008.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration. Carbon fiber reinforced plastics-Determination of void content and fiber volume content: GB/T 3365—2008[S]. Beijing: Standards Press of China, 2008(in Chinese). [23] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 定向纤维增强聚合物基复合材料拉伸性能试验方法: GB/T 3354—2014[S]. 北京: 中国标准出版社, 2014.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration. Test method for tensile properties of orientation fiber reinforced polymer matrix composite materials: GB/T 3354—2014[S]. Beijing: Standards Press of China, 2014(in Chinese). [24] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 纤维增强塑料面内压缩性能试验方法: GB/T 5258—2008[S]. 北京: 中国标准出版社, 2009.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration. Fibre-reinforced plastic composites-Determination of compressive properties in the in-plane direction: GB/T 5258—2008[S]. Beijing: Standards Press of China, 2009(in Chinese). [25] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 定向纤维增强聚合物基复合材料弯曲性能试验方法: GB/T 3356—2014[S]. 北京: 中国标准出版社, 2014.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration. Test method for flexural properties of orientational fiber reinforced polymer metrix composite materials: GB/T 3356—2014[S]. Beijing: Standards Press of China, 2014(in Chinese). [26] 中华人民共和国工业和信息化部. 纤维增强塑料短梁法测定层间剪切强度: JC/T 773—2010[S]. 北京: 建材工业出版社, 2011.Ministry of Industry and Information Technology of the People's Republic of China. Fibre-reinforced plastics composites-Determination of apparent interlaminar shear strength by short-beam method: JC/T 773—2010[S]. Beijing: China Building Materials Press, 2011(in Chinese). [27] 石佩洛, 梁洪涛, 白雪莲, 等. 树脂η*和Tg对C/E预浸料黏性的表征[J]. 宇航材料工艺, 2016(6): 79-81. https://www.cnki.com.cn/Article/CJFDTOTAL-YHCG201606016.htmSHI P L, LIANG H T, BAI X L, et al. Characterization of C/E prepreg' tack properties by η* and Tg of resins[J]. Aerospace Materials and Technology, 2016(6): 79-81(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-YHCG201606016.htm [28] 李婷婷, 李艳霞, 陈超, 等. 603环氧树脂体系固化动力学模型的建立与验证[J]. 复合材料学报, 2018, 35(1): 95-102. https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201801013.htmLI T T, LI Y X, CHEN C, et al. Establishment and verification of curing kinetics model of 603 epoxy resin system[J]. Acta Materiae Compositae Sinica, 2018, 35(1): 95-102(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201801013.htm -

下载:

下载: