Interfacial crack growth of delaminated composite laminates under hygrothermal environment

-

摘要:

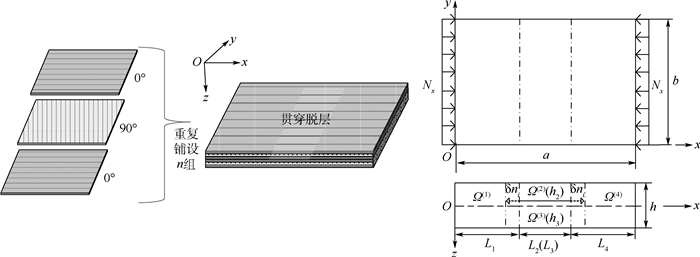

处于恶劣湿热环境中的复合材料层合结构,受湿热残余应变和残余应力的作用,易产生局部屈曲和分层扩展。考虑湿热效应和脱层间接触效应的影响,对含脱层复合材料中厚板的非线性屈曲和界面裂纹扩展行为进行了理论分析。基于可动边界变分原理,建立层合板在湿-热-力载荷作用下的总势能,并推导出非线性后屈曲控制方程和脱层扩展能量释放率。应用摄动法和Galerkin法求解控制方程,获得以面内压缩载荷-挠度曲线为特征的含脱层复合材料层合板的后屈曲路径。根据求得的后屈曲解及Griffith断裂准则,确定脱层扩展临界压力的理论解。通过开发MATLAB程序,综合讨论了脱层尺寸、湿热环境对脱层复合材料层合板屈曲和扩展载荷的影响。研究结果与ABAQUS有限元解和经典理论解进行比较,验证了理论分析的有效性。结果表明:湿热环境会显著降低脱层复合材料层合板的屈曲载荷和扩展载荷。此外,忽略复合材料层合板的横向剪切应变将导致对层合板承载能力的高估。

Abstract:The laminated composite structures in harsh hygrothermal environment are easy to undergo premature buckling and delamination propagation. This paper proposes a theoretical study on the nonlinear buckling and interfacial crack propagation of thick plate containing delamination by considering the hygrothermal effect and the contact effect. Based on the variational principles of variable boundary, the total potential energy of the laminates subjected to hygro-thermal-mechanical loading is established from which the governing equations for nonlinear post-buckling and the expression of energy release rate for delamination propagation are derived. The post-buckling equilibrium paths of the laminates characterized by the in-plane load vs deflection amplitude curves are determined via perturbation technique and Galerkin approach. With the available solutions from post-buckling analysis, the theoretical solution of threshold load corresponding to the delamination propagation is determined according to Griffith fracture criterion. By developing MATLAB program, numerical calculations are performed to discuss the effect of the temperature, the hygroscopic concentration and the delamination conditions on the buckling and delamination propagation threshold load. The solutions are compared with the results from ABAQUS finite element analysis and the predictions obtained from classical laminated plate theory, both showing good agreements with the presented theoretical solutions. Results show that hygro-thermal environment reduce the buckling load and the delamination propagation threshold load. Besides, neglecting the transverse shear strain may overestimate the load-carrying capacity of the laminates.

-

表 1 含脱层复合材料层合板的有限元方法与理论方法的无量纲屈曲载荷比较

Table 1. Compassion of non-dimensional buckling load between FEM and present method of delaminated composite laminates

ΔT/℃ L2/a 无量纲屈曲载荷 Diff./% FEM FSDT 0.1 8 477 8 368 1.29 0 0.3 7 031 6 720 4.42 0.5 6 091 5 844 4.06 0.1 8 329 8 220 1.31 25 0.3 6 881 6 574 4.46 0.5 5 941 5 697 4.11 0.1 8 031 7 925 1.32 75 0.3 6 581 6 280 4.57 0.5 5 640 5 402 4.22 表 2 含脱层复合材料层合板的经典层合板理论和剪切理论无量纲屈曲载荷和无量纲临界扩展载荷比较

Table 2. Compassion of non-dimensional buckling load and non-dimensional threshold between CLPT and present method of delaminated composite laminates

h2/h L2/a Ncr Npl Diff.Ncr/% Diff.Npl/% CLPT[18] FSDT CLPT[18] FSDT 0.1 9 527 9 050 9 706 9 055 5.01 6.71 0.1 0.2 8 991 8 553 9 039 8 620 4.87 4.64 0.3 8 549 8 145 5 578 8 181 4.73 4.63 0.1 8 001 7 623 8 031 7 721 4.72 3.86 0.3 0.2 6 633 6 349 6 658 6 395 4.28 3.95 0.3 5 738 5 516 5 758 5 548 3.87 3.65 0.1 7 029 6 753 7 065 6 831 3.93 3.31 0.5 0.2 5 477 5 294 5 501 5 338 3.34 2.96 0.3 4 562 4 428 4 583 4 462 2.94 2.64 注:Diff.Ncr为Ncr的Diff.,Diff.Npl为Npl的Diff.。 -

[1] 赵丽滨, 龚愉, 张建宇. 纤维增强复合材料层合板分层扩展行为研究进展[J]. 航空学报, 2019, 40(1): 522509. https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201901012.htmZHAO L B, GONG Y, ZHANG J Y. A survey on delamination growth behavior in fiber reinforced composite laminates[J]. Acta Aeronautica et Astronautica Sinica, 2019, 40(1): 522509(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201901012.htm [2] CHAI H, BABCOCK C D, KNAUSS W G. One dimensional modeling of failure in laminated plates by delamination buckling[J]. International Journal of Solids and Structures, 1981, 17(11): 1069-1083. doi: 10.1016/0020-7683(81)90014-7 [3] 刘述伦, 薛江红, 王璠, 等. 含脱层纤维增强复合材料层合板在湿热环境下的屈曲分析[J]. 工程力学, 2015, 32(3): 1-8. https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201503002.htmLIU S L, XUE J H, WANG F, et al. Buckling analysis of fiber-reinforced laminated composite plate with delamination under hygrothermal environments[J]. Engineering Mechanics, 2015, 32(3): 1-8(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201503002.htm [4] 周宇, 沈峰, 史耀辉, 等. 含纤维搭桥的正交各向异性材料非线性矩形脱层屈曲分析[J]. 力学季刊, 2017, 38(4): 675-680. https://www.cnki.com.cn/Article/CJFDTOTAL-SHLX201704008.htmZHOU Y, SHEN F, SHI Y H, et al. Analysis of non-linear buckling of rectangular delamination in orthotropic materials with fiber bridging[J]. Chinese Quarterly of Mechanics, 2017, 38(4): 675-680(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-SHLX201704008.htm [5] 李萍, 金福松, 简方, 等. 含脱层单向铺设层合梁非线性后屈曲分析[J]. 工程力学, 2019, 36(11): 239-249. https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201911026.htmLI P, JIN F S, JIAN F, et al. Nonlinear post-buckling analysis of unidirectional laminated beams with delamination[J]. Engineering Mechanics, 2019, 36(11): 239-249(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201911026.htm [6] KÖLLNER A, VÖLLMECKE C. An analytical framework to extend the general structural stability analysis by considering certain inelastic effects-theory and application to delaminated composites[J]. Composite Structures, 2017, 170: 261-270. doi: 10.1016/j.compstruct.2017.01.088 [7] KÖLLNER A, VÖLLMECKE C. Post-buckling behaviour and delamination growth characteristics of delaminated composite plates[J]. Composite Structures, 2018, 203: 777-788. doi: 10.1016/j.compstruct.2018.03.010 [8] 刘人怀, 薛江红. 复合材料层合板壳非线性力学的研究进展[J]. 力学学报, 2017, 49(3): 487-506. doi: 10.3969/j.issn.1006-6616.2017.03.016LIU R H, XUE J H. Development of nonlinear mechanics for laminated composite plates and shells[J]. Chinese Journal of Theoretical and Applied Mechanics, 2017, 49(3): 487-506(in Chinese). doi: 10.3969/j.issn.1006-6616.2017.03.016 [9] NIKRAD S F, KEYPOURSANGSARI S, ASADI H, et al. Computational study on compressive instability of composite plates with off-center delaminations[J]. Computer Methods in Applied Mechanics and Engineering, 2016, 310: 429-459. https://www.sciencedirect.com/science/article/pii/S0045782516307794 [10] WANG K K, ZHAO L B, HONG H M, et al. An extended analytical model for predicting the compressive failure behaviors of composite laminate with an arbitrary elliptical delamination[J]. International Journal of Solids and Structures, 2020, 185-186: 439-447. [11] SHABANIJAFROUDI N, GANESAN R. A penalty function based delamination model for postbuckling analysis of composite plates with delamination[J]. Composite Structures, 2020, 261: 113273. [12] PEREIRA A B, MORAIS A B. Mixed mode Ⅰ+Ⅱ interlaminar fracture of carbon/epoxy laminates[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(2): 322-333. https://www.sciencedirect.com/science/article/pii/S1359835X07002151 [13] 郑伟玲, 郑龙席. 复合材料层合板界面裂纹能量释放率解析方法研究[J]. 西北工业大学学报, 2019, 37(1): 137-142. https://www.cnki.com.cn/Article/CJFDTOTAL-XBGD201901020.htmZHENG W L, ZHENG L X. Analytical energy release rate of interfacial crack in composite laminates[J]. Journal of Northwestern Polytechnical University, 2019, 37(1): 137-142(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-XBGD201901020.htm [14] 任雷, 盛冬发. 单向纤维增强复合材料板Ⅰ型裂纹尖端应力场的有限元分析[J]. 西南林业大学学报(自然科学), 2018, 38(3): 181-186. https://www.cnki.com.cn/Article/CJFDTOTAL-YNLX201803025.htmREN L, SHENG D F. The finite element analysis for stress field of unidirectional fibre-reinforced composite plate mode Ⅰ crack tip[J]. Journal of Southwest Forestry University(Natural Science), 2018, 38(3): 181-186(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-YNLX201803025.htm [15] TAY T E, SUN X S, TAN V B C. Recent efforts toward modeling interactions of matrix cracks and delaminations: An integrated XFEM-CE approach[J]. Advanced Composite Materials, 2014, 23(5-6): 391-408. [16] 邓健, 卢天健, 尹乔之. 复合材料MMB试件Ⅰ-Ⅱ混合型层间裂纹扩展分析[J]. 航空学报, 2021, 42(2): 224241. https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB202102014.htmDENG J, LU T J, YIN Q Z. On the Ⅰ-Ⅱ mixed interlaminar crack propagation of composite MMB specimens[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(2): 224241(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB202102014.htm [17] TANG M Q, XUE J H, YUAN H, et al. Macro-micro analysis for anti-penetrating postbuckling of fiber reinforced, deboned laminates with contact effects[J]. International Journal of Applied Mechanics, 2014, 6(4): 1450044. [18] XUE J H, JIN F S, ZHANG J W, et al. Post-buckling induced delamination propagation of composite laminates with bi-nonlinear properties and anti-penetrating interaction effects[J]. Composites Part B, 2019, 166: 148-161. https://www.sciencedirect.com/science/article/pii/S1359836818327604 [19] XUE J H, XIA F, ZHANG J W, et al. Multiscale studies on the nonlinear vibration of delaminated composite laminates-global vibration mode with micro buckles on the interface[J]. Scientific Reports, 2017, 7(1): 4468. https://www.nature.com/articles/s41598-017-04570-3 [20] 沈观林, 胡更开. 复合材料力学[M]. 2版. 北京: 清华大学出版社, 2006: 143-153.SHEN G L, HU G K. Mechanics of composite materials[M]. 2nd ed. Beijing: Tsinghua University Press, 2006: 143-153(in Chinese). -

下载:

下载: