Properties of gas discharge electron beam coaxial wire of fuse additive manufacturing and microstructure of TC4 titanium alloy

-

摘要:

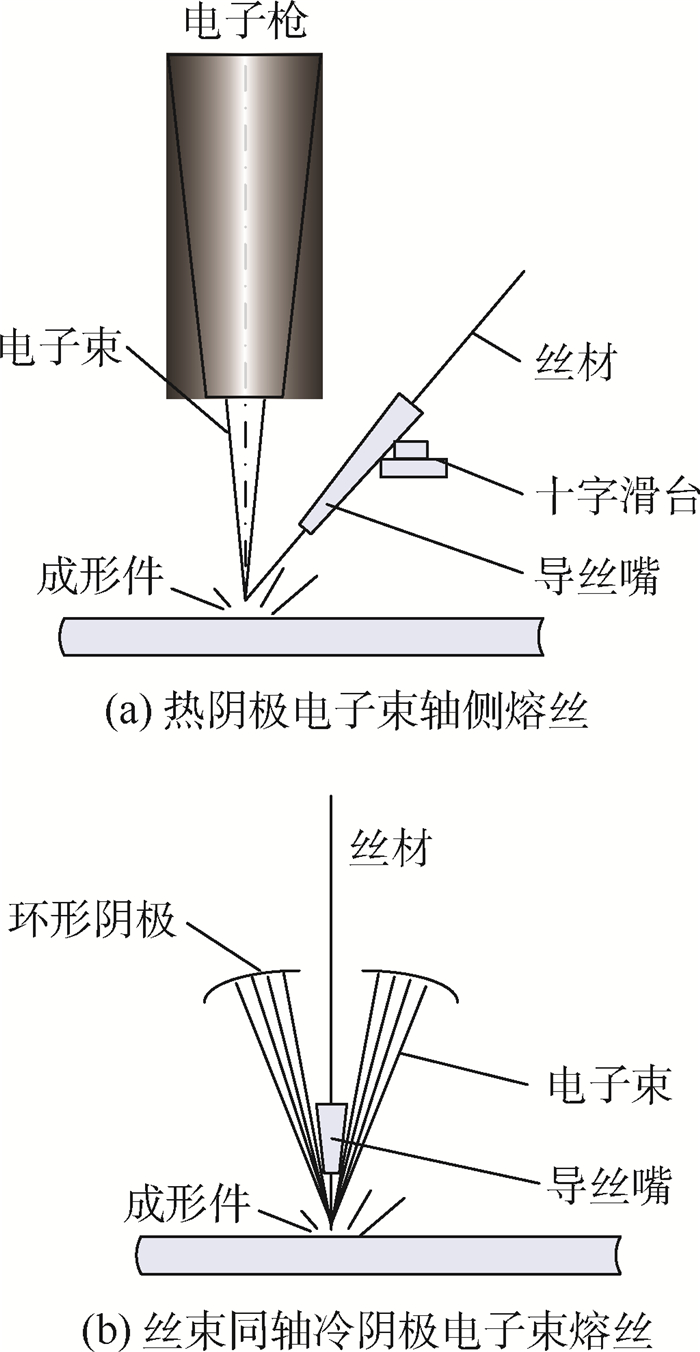

针对热阴极电子束轴侧熔丝与丝束同轴冷阴极电子束熔丝方法的特点进行分析,研究了丝束同轴冷阴极电子束熔丝增材制造熔滴过渡特点及获得滴状过渡和搭桥过渡方式需要满足的条件。采用直径2 mm的TC4钛合金丝材制备出丝束同轴冷阴极电子束熔丝增材制造的钛合金试样,对其微观组织进行分析,结果表明:与常规热阴极电子束轴侧熔丝成形的工艺相比,丝束同轴冷阴极电子束熔丝成形试样的组织表现为等轴晶与柱状晶层层交替叠加的状态,柱状晶与等轴晶尺寸明显减小,表明成形试样的晶粒细化,力学性能得到提高。

Abstract:Based on the analysis of fuse additive manufacturing using hot cathode electron beams with axial side feeding wires and gas discharge electron beam coaxial wire, the characteristics of droplet transfer of the gas discharge electron beam coaxial wire fuse additive manufacturing have been analyzed, and the conditions for obtaining droplet transfer and bridging transfer are also studied. A TC4 titanium alloy sample is made by gas discharge electron beam coaxial wire of fuse additive manufacturing by the mode of droplet bridging of

Φ 2 mm TC4 wire. The microstructure of the sample is compared with that manufactured by hot cathode electron beam fuse additive. Results show that the columnar and equiaxed grains of the sample overlap alternately layer by layer with an obvious decrease in their sizes, indicating that the sample grains of the sample are refined and that its mechanical properties can be improved. -

表 1 丝束同轴冷阴极电子束熔丝增材制造样机基本参数

Table 1. Basic parameters of equipment of gas discharge electron beam coaxial wire of fuse additive manufacturing

参数 数值 工作电压U/kV -20 最大束流Ib/mA 1 000 成形速度/(kg·h-1) >5 成形范围S/(mm×mm×mm) 400×400×500 成形精度ε/mm 0.2 表 2 热阴极电子束轴侧熔丝增材制造样机基本参数

Table 2. Basic parameters of equipment of fuse additive manufacturing with axial side feeding wire

参数 数值 工作电压U/kV -60 最大束流Ib/mA 500 成形速度/(kg·h-1) >5 成形范围S/(mm×mm×mm) 3 000×1 800×1 000 成形精度ε/mm 0.2 表 3 丝束同轴冷阴极电子束熔丝成形工艺参数

Table 3. Technique parameters of gas discharge electron beam coaxial wire of fuse additive manufacturing

参数 数值 气流量Q/(mL·min-1) 120 工作电压Uhv/kV -20 束流Ib/mA 300 送丝速度Vs/(mm·s-1) 50 工作台运动速度Vx/(mm·s-1) 60 表 4 热阴极电子束轴侧熔丝增材制造工艺参数

Table 4. Technique parameters of fuse additive manufacturing with axial side feeding wire

参数 数值 气流量Q/(mL·min-1) 0 工作电压Uhv/kV -60 束流Ib/mA 150 送丝速度Vs/(mm·s-1) 30 工作台运动速度Vx/(mm·s-1) 50 -

[1] 尹凡, 王克鸿, 冯曰海, 等. 电弧填丝增材制造的宽度尺寸建模及分析[J]. 机械制造与自动化, 2018, 47(3): 119-122. https://www.cnki.com.cn/Article/CJFDTOTAL-ZZHD201803029.htmYIN F, WANG K H, FENG Y H, et al. Width dimension modeling and analysis of wire and arc additive manufacture[J]. Machine Building & Automation, 2018, 47(3): 119-122(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-ZZHD201803029.htm [2] 曹嘉明. 电弧熔丝增材制造高强钢零件工艺基础研究[D]. 武汉: 华中科技大学, 2017.CAO J M. Fundamental study on wire and arc additive manufacturing technique for high strength steel components[D]. Wuhan: Huazhong University of Science and Technology, 2017(in Chinese). [3] 王帅, 顾惠敏, 王伟, 等. ZL205A电弧熔丝增材制造堆积体的组织与性能[J]. 稀有金属材料与工程, 2019, 48(9): 2910-2916. https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201909028.htmWANG S, GU H M, WANG W, et. al. Microstructure and mechanical properties of ZL205A aluminum alloy wall produced by wire arc additive manufacturing[J]. Rare Metal Materials and Engineering, 2019, 48(9): 2910-2916(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201909028.htm [4] 方力, 侯智文, 黄俊润, 等. 电弧熔丝增材制造复合填充路径规划算法[J]. 南京航空航天大学学报, 2019, 51(1): 98-104. https://www.cnki.com.cn/Article/CJFDTOTAL-NJHK201901015.htmFANG L, HOU Z W, HUANG J R, et al. Composite filling path planning algorithm for wire and ARC additive manufacturing[J]. Journal of Nanjing University of Aeronautics and Astronautics, 2019, 51(1): 98-104(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-NJHK201901015.htm [5] 郭一蒙. 铝合金激光熔丝增材制造工艺研究[D]. 南京: 南京理工大学, 2018.GUO Y M. The laser additive manufacturing technology of aluminum alloy with melting wire[D]. Nanjing: Nanjing University of Science and Technology, 2018(in Chinese). [6] 黄安国, 刘博, 郑增超, 等. 激光熔丝增材制造丝材过渡状态的电磁振动监测方法[J]. 机械工程学报, 2018, 54(2): 34-40. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201802005.htmHUANG A G, LIU B, ZHENG Z C, et al. Electromagnetic vibration monitoring method for liquid transfer mode in wire feeding based laser additive manufacturing[J]. Journal of Mechanical Engineering, 2018, 54(2): 34-40(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201802005.htm [7] 李慧敏. 激光熔丝增材制造工艺特性研究[D]. 重庆: 重庆大学, 2017.LI H M. Study on the process characteristics of wire based laser additive manufacturing[D]. Chongqing: Chongqing University, 2017(in Chinese). [8] 刘思余, 冯曰海, 占彬, 等. 堆覆速度对等离子弧双填丝增材制造碳钢堆覆层组织和性能的影响[J]. 机械工程材料, 2018, 42(9): 69-72. https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201809016.htmLIU S Y, FENG Y H, ZHAN B, et al. Effect of deposition speed on microstructure and properties of double-wire and plasma arc additive manufactured carbon steel stacking layer[J]. Materials for Mechanical Engineering, 2018, 42(9): 69-72(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201809016.htm [9] 陈国庆, 树西, 张秉刚, 等. 国内外电子束熔丝沉积增材制造技术发展现状[J]. 焊接学报, 2018, 39(8): 123-128. https://www.cnki.com.cn/Article/CJFDTOTAL-HJXB201808027.htmCHEN G Q, SHU X, ZHANG B G, et al. Development status of electron beam fuse deposition additive manufacturing technology at home and abroad[J]. Transactions of the China Welding Institution, 2018, 39(8): 123-128(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-HJXB201808027.htm [10] 巩水利, 锁红波, 李怀学. 金属增材制造技术在航空领域的发展与应用[J]. 航空制造技术, 2013(13): 66-71. https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ201313017.htmGONG S L, SUO H B, LI H X. Development and application of metal additive manufacturing technology[J]. Aeronautical Manu-facturing Technology, 2013(13): 66-71(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ201313017.htm [11] DENBNOVETSKY S V, MELNYK V G, MELNYK I V. High-voltage, glow-discharge electron sources and possibilities of its application in industry for realizing different technological operations[J]. IEEE Transactions on Plasma Science, 2003, 31(5): 987-993. [12] DENBNOVETSKY S V, MELNYK I V, MELNYK V G, et al. High voltage glow discharge electron guns and its advanced application examples in electronic industry[C]//2016 International Conference "Radio Electronics & Info Communications". Piscataway: IEEE Press, 2016: 16450310. [13] FEINAEUGLE P, MATTAUSCH G, SCHMIDT S, et al. A new generation of plasma-based electron beam sources with high power density as a novel tool for high-rate PVD[C]//Society of Vacuum Coaters 54th Annual Technical Conference Proceedings, 2011. [14] ZHANG J H, YANG Y, CAO S, et al. Fine equiaxed β grains and superior tensile property in Ti-6Al-4V alloy deposited by coaxial electron beam wire feeding additive manufacturing[J]. Acta Metallurgica Sinica(English Letters), 2020, 33(10): 1311-1320. [15] 叶焕中. 电弧焊及电渣焊[M]. 2版. 北京: 机械工业出版社, 1988.YE H Z. Arc welding and electroslag welding[M]. 2nd ed. Beijing: China Machine Press, 1988(in Chinese). -

下载:

下载: