-

摘要:

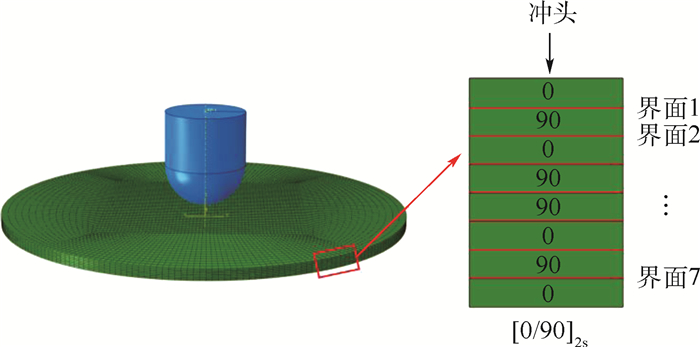

纤维增强复合材料层板对低速冲击事件敏感,冲击产生的损伤会导致材料结构承载性能及使用寿命大幅下降。基于此,提出了一种基于连续介质损伤力学的有限元模型,研究了复合材料层板低速倾斜冲击力学行为。采用Hashin准则结合渐进退化模型预测层内损伤起始和演化;采用界面单元结合双线性Traction-Separation本构关系模拟层间分层;编写用户材料VUMAT子程序,实现基于ABAQUS/Explicit软件平台的数值求解。数值计算结果与现有正冲击下实验数据吻合较好,验证了模型的有效性。探讨了冲击角度、冲击能量对复合材料层板倾斜冲击力学性能的影响,分析倾斜冲击下层板损伤模式及失效机理,为复合材料结构倾斜冲击问题数值分析提供参考。

Abstract:Fiber reinforced composite laminates are sensitive to low velocity impact events, and the induced damage extensively reduces the load-bearing capacity and service life of composite structures. A continuum damage mechanics based finite element model is proposed to investigate the mechanical behavior of composite laminates under low velocity oblique impact. The Hashin criteria and a gradual degradation model are employed to predict the intra-laminar damage initiation and evolution; cohesive elements ruled by the bilinear Traction-Separation constitutive relation are applied to simulate delamination. A user material subroutine VUMAT is then developed and implemented to obtain the numerical solution based on ABAQUS/Explicit solver. The numerical results are largely consistent with the available experimental data under normal impact, thus validating the effectiveness of the proposed model. The effects of the impact angle and impact energy on the oblique impact properties of composite laminates are discussed and the damage mode and failure mechanism are analyzed in detail, providing insight into the numerical study on general oblique impact problems in composite structures.

-

Key words:

- composite laminate /

- low-velocity impact /

- oblique impact /

- damage /

- numerical simulation

-

表 1 单向复合材料性能参数

Table 1. Material properties of unidirectional composite

参数 数值 密度/(kg·m-3) 1 600 弹性性能/GPa E11=153; E22= E33=10.3

G12= G13=6;G23=3.7

v12= v13=0.3; v23=0.4强度性能/MPa XT=2 537; XC=1 580

YT=82; YC=236; S=117.45

S12= S13=90; S23=40断裂韧性/(N·mm-1) Gft= Gfc =10; Gmt= Gmc=1 表 2 界面材料性能参数

Table 2. Material properties of interface material

参数 数值 密度/(kg·m-3) 1 200 K/(N·mm-3) 200 000 N/MPa 62.3 S=T/MPa 92.3 GⅠC/(N·mm-1) 0.28 GⅡC= GⅢC/(N·mm-1) 0.79 -

[1] 崔旭, 李斌, 王朔, 等. GLARE层板低速冲击的实验与模拟[J]. 航空材料学报, 2019, 39(2): 68-74. https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201902011.htmCUI X, LI B, WANG S, et al. Simulation on low velocity impact to GLARE laminate based on ABAQUS[J]. Journal of Aeronautical Materials, 2019, 39(2): 68-74(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201902011.htm [2] SOLVER I, THORSSON A, SUNIL P, et al. Experimental investigation of composite laminates subject to low-velocity edge on impact and compression after impact[J]. Composite Structures, 2018, 186: 335-346. doi: 10.1016/j.compstruct.2017.11.084 [3] HESAM Y, ALI N, HAMED S, et al. Experimental and numerical investigation of low velocity impact on electrospun nanofiber modified composite laminates[J]. Composite Structures, 2018, 200: 507-514. doi: 10.1016/j.compstruct.2018.05.146 [4] DAMGHANI M, ERSOY N, PIORKOWSKI M, et al. Experimental evaluation of residual tensile strength of hybrid composite aerospace materials after low velocity impact[J]. Composites Part B, 2019, 179: 107537. doi: 10.1016/j.compositesb.2019.107537 [5] MIAO H R, WU Z Y, YING Z P, et al. The numerical and experimental investigation on low-velocity impact response of composite panels: Effect of fabric architecture[J]. Composite Structures, 2019, 227: 111343. doi: 10.1016/j.compstruct.2019.111343 [6] NATSUKI T, YOSHIZAWA K, BAO L M, et al. Theoretical analysis of low-velocity impact response in two-layer laminated plates with an elastic medium layer[J]. Composite Structures, 2017, 162: 308-312. doi: 10.1016/j.compstruct.2016.11.069 [7] 王计真, 刘小川. 预加载复合材料层合薄板低速冲击理论分析[J]. 应用力学学报, 2018, 35(6): 1248-1253. https://www.cnki.com.cn/Article/CJFDTOTAL-YYLX201806011.htmWANG J Z, LIU X C. Theoretical analysis of low speed impact of preloaded composite laminates[J]. Chinese Journal of Applied Mechanics, 2018, 35(6): 1248-1253(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-YYLX201806011.htm [8] PEREZ M, MARTINEZ X, OLLER S, et al. Impact damage prediction in carbon fiber-reinforced laminated composite using the matrix-reinforced mixing theory[J]. Composite Structures, 2013, 104: 239-248. doi: 10.1016/j.compstruct.2013.04.021 [9] ZHOU Y Z, WEN P Y, WANG S N. Finite element analysis of a modified progressive damage model for composite laminates under low-velocity impact[J]. Composite Structures, 2019, 225: 111113. doi: 10.1016/j.compstruct.2019.111113 [10] WAN Y, DIAO C Y, YANG B, et al. GF/epoxy laminates embedded with wire nets: A way to improve the low-velocity impact resistance and energy absorption ability[J]. Composite Structures, 2018, 202: 818-835. doi: 10.1016/j.compstruct.2018.04.041 [11] JIANG Y X, ZHANG B Y, WEI J S, et al. Study on the impact resistance of polyurea-steel composite plates to low velocity impact[J]. International Journal of Impact Engineering, 2019, 133: 103357. doi: 10.1016/j.ijimpeng.2019.103357 [12] FENG D, AYMERICH F. Finite element modelling of damage induced by low-velocity impact on composite laminates[J]. Composite Structures, 2014, 108: 160-171. [13] ZHANG C, DUODU E, GU J N, et al. Finite element modeling of damage development in cross-ply composite laminates subjected to low velocity impact[J]. Composite Structures, 2017, 173: 219-227. doi: 10.1016/j.compstruct.2017.04.017 [14] PASCAL F, DORICAL O, NAVARRO P, et al. Impact damage prediction in thin woven composite laminates. Part Ⅰ: Modeling strategy and validation[J]. Composite Structures, 2018, 190: 32-42. doi: 10.1016/j.compstruct.2018.02.007 [15] PASCAL F, ROGANI A, MAHMOUD B, et al. Impact damage prediction in thin woven composite laminates. Part Ⅱ: Application to normal and oblique impacts on sandwich structure[J]. Composite Structures, 2018, 190: 43-51. doi: 10.1016/j.compstruct.2018.02.013 [16] KUMAR R, MUKHOPADHYAY T, NASKAR S, et al. Stochastic low-velocity impact analysis of sandwich plates including the effects of obliqueness and twist[J]. Thin-Walled Structures, 2019, 145: 106411. doi: 10.1016/j.tws.2019.106411 [17] 徐瑀童, 左洪福, 陆晓华, 等. 复合材料低速冲击损伤评估数值分析与试验研究[J]. 振动与冲击, 2019, 38(3): 149-155. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201903022.htmXU Y T, ZUO H F, LU X H, et al. Numerical analysis and experimental study on low speed impact damage evaluation of composite materials[J]. Journal of Vibration and Shock, 2019, 38(3): 149-155(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201903022.htm [18] LAPCZYK I, HURTADO J. Progressive damage modeling in fiber reinforced materials[J]. Composites Part A, 2007, 38(11): 2333-2341. doi: 10.1016/j.compositesa.2007.01.017 [19] SHI Y, SWAIT T, SOUTIS C. Modelling damage evolution in composite laminates subjected to low velocity impact[J]. Composite Structures, 2012, 94(9): 2902-2913. doi: 10.1016/j.compstruct.2012.03.039 -

下载:

下载: