-

摘要:

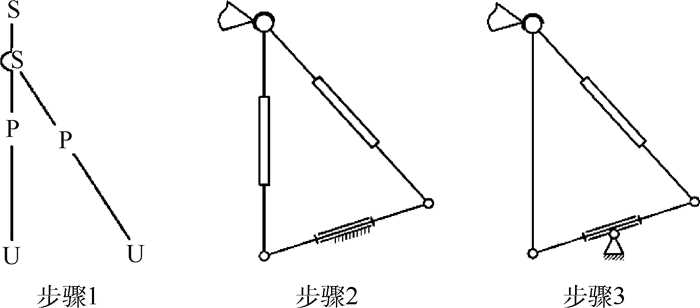

为满足航天飞行器壳体套装过程中位姿调整机构刚度大、精度高的要求,对传统的支链结构进行有针对性的改进,设计了一种支链为闭环结构的新型5-U(RRP)S/(8U)PU并联机构,并进行了分析研究。应用螺旋理论计算机构的自由度;建立封闭矢量方程,进行运动学正反解;应用螺旋理论求解机构的全雅可比矩阵;利用杆长约束条件绘制机构的定姿态工作空间;通过求解静刚度矩阵分析机构的刚度随位姿的变化情况;利用软件进行仿真,并与一般机构进行对比。通过分析,验证了该机构的可行性和实际应用价值,为实现航天飞行器壳体套装的自动化奠定基础。

Abstract:In order to meet the requirements of high stiffness and accuracy of the position and posture adjusting mechanism in the assembly process of spacecraft shell, a novel 5-U(RRP)S/(8U)PU parallel mechanism with closed-loop limbs, which are improved from conventional limb structure, is proposed and analyzed. The degree of freedom of the mechanism is calculated by screw theory. The positional positive and negative solutions are figured out through establishing the seal vector constraints equation. The complete Jacobian matrix is calculated by screw theory. The fixed posture workspace is drawn by the restrained link length. The changes of mechanism stiffness with the position and posture are analyzed by solving the static stiffness matrix. The software is used to simulate and compare with the general mechanism. Through the above analysis, the feasibility and practical application value are verified, which lays the foundation for the automatic assembly process of spacecraft shell.

-

Key words:

- parallel mechanism /

- closed-loop structure /

- high stiffness /

- high accuracy /

- kinematics analysis

-

表 1 并联机构尺寸参数

Table 1. Dimension parameters of parallel mechanism

参数 数值 a/mm 200 b/mm 160 c/mm 160 d/mm 100 r/mm 215 l1/mm 220 l2/mm 340 θ6m/(°) 60 l6min/mm 100 l6max/mm 800 l3, imin/mm 150 l3, imax/mm 550 θimin/(°) 15 θimax/(°) 45 表 2 各支链驱动副位移量

Table 2. Displacement of driving joint on each limb

动平台沿z方向的坐标值/mm P1位移量/mm P2/P5位移量/mm P3/P4位移量/mm 本文 对比 本文 对比 本文 对比 300 0 0 0 0 0 0 310 18.03 10.04 18.03 10.01 16.85 9.74 320 36.07 20.03 36.06 19.96 33.63 19.32 330 54.15 30.18 54.12 30.11 50.55 29.07 340 72.26 40.14 72.19 40.08 67.32 38.66 350 90.48 50.18 90.37 50.06 84.26 48.31 360 108.65 60.16 108.56 60.11 101.05 58.15 370 126.88 70.11 126.74 70.09 117.76 67.63 380 144.81 80.18 144.73 80.12 134.54 77.24 390 162.93 90.01 162.75 89.95 151.38 96.99 400 180.11 100.04 179.94 100.00 168.01 96.51 表 3 各支链驱动副电机运行速度

Table 3. Motor operation speed of driving joint on each limb

支链驱动副编号 速度/(mm·s-1) P1 -2 P2 2 P3 4 P4 4 P5 2 表 4 各支链驱动副受力

Table 4. Force of driving joint on each limb

电机工作时间/s P1受力/N P2/P5受力/N P3/P4受力/N 本文 对比 本文 对比 本文 对比 0 -323.29 -610.14 38.46 72.19 158.15 -291.08 0.5 -338.51 -673.73 49.51 113.77 159.93 -298.71 1.0 -354.46 -737.49 61.43 155.43 161.85 -306.40 1.5 -365.83 -801.16 72.59 197.16 163.71 -314.15 2.0 -385.18 -864.83 84.16 238.86 165.65 -321.84 2.5 -400.57 -1928.53 95.54 280.52 167.58 -329.53 3.0 -416.16 -992.24 107.37 322.24 169.41 -337.27 3.5 -431.19 -1055.96 118.51 363.93 171.35 -344.91 4.0 -447.74 -1119.67 130.74 405.66 173.25 -352.62 4.5 -462.57 -1183.34 141.53 447.31 175.17 -360.30 5.0 -478.15 -1247.18 153.44 489.25 177.06 -368.43 -

[1] 谷良贤, 龚春林.航天飞行器设计[M].西安:西北工业大学出版社, 2016:37-40.GU L X, GONG C L.Design of aerospace vehicle[M].Xi'an:Northwestern Polytechnical University Press, 2016:37-40(in Chinese). [2] 刘鹏程, 杜毅民.导弹总体测试工程化的几个问题[J].航空兵器, 2006(4):50-53. doi: 10.3969/j.issn.1673-5048.2006.04.013LIU P C, DU Y M.Problems of engineering design for missile system test[J].Aero Weaponry, 2006(4):50-53(in Chinese). doi: 10.3969/j.issn.1673-5048.2006.04.013 [3] 马政伟, 李卫东, 万敏, 等.飞机侧壁部件装配调姿机构的设计与分析[J].北京航空航天大学学报, 2014, 40(2):280-284. http://bhxb.buaa.edu.cn/CN/abstract/abstract12862.shtmlMA Z W, LI W D, WAN M, et al.Design and analysis of flexible fixture for aircraft side panels[J].Journal of Beijing University of Aeronautics and Astronautics, 2014, 40(2):280-284(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract12862.shtml [4] 文福安, 杨光.并联机器人机构概述[J].机械科学与技术, 2000, 19(1):69-72. doi: 10.3321/j.issn:1003-8728.2000.01.026WEN F A, YANG G.Summary of parallel robot mechanism[J].Mechanical Science and Technology, 2000, 19(1):69-72(in Chinese). doi: 10.3321/j.issn:1003-8728.2000.01.026 [5] KONG X.Type synthesis of 5-DOF parallel manipulators based on screw theory[M].New York:John Wiley & Sons, 2005. [6] LI Q C, HUANG Z, HERV J M.Displacement manifold method for type synthesis of lower-mobility parallel mechanisms[J].Science in China, 2004, 47(6):641-650. doi: 10.1360/03ye0352 [7] 杨廷力.机器人机构拓扑结构学[M].北京:机械工业出版社, 2004:12-16.YANG T L.Topology structure design of robot mechanisms[M].Beijing:China Machine Press, 2004:12-16(in Chinese). [8] 唐卫星, 马履中, 石奇端, 等.3T-2R五自由度并联机构的型综合[J].中国机械工程, 2007, 18(20):2460-2463. doi: 10.3321/j.issn:1004-132x.2007.20.016TANG W X, MA L Z, SHI Q D, et al.Type synthesis of 3T-2R parallel mechanism[J].China Mechanical Engineering, 2007, 18(20):2460-2463(in Chinese). doi: 10.3321/j.issn:1004-132x.2007.20.016 [9] 李秦川.对称少自由度并联机器人型综合理论及新机型综合[D].秦皇岛: 燕山大学, 2003: 57-68. http://cdmd.cnki.com.cn/Article/CDMD-10216-2004061702.htmLI Q C.Type synthesis theory of lower-mobility parallel mechanisms and synthesis of new architectures[D].Qinhuangdao: Yanshan University, 2003: 57-68(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10216-2004061702.htm [10] SONG Y M, LIAN B B, SUN T, et al.A novel five-degree-of-freedom parallel manipulator and its kinematic optimization[J].Journal of Mechanisms and Robotics, 2014, 6(4):041008. doi: 10.1115/1.4027742 [11] DONG C, LIU H, YUE W, et al.Stiffness modeling and analysis of a novel 5-DOF hybrid robot[J].Mechanism and Machine Theory, 2018, 125:80-93. doi: 10.1016/j.mechmachtheory.2017.12.009 [12] XU P, CHEUNG C F, LI B, et al.Kinematics analysis of a hybrid manipulator for computer controlled ultra-precision freeform polishing[J].Robotics and Computer-Integrated Manufacturing, 2017, 44:44-56. doi: 10.1016/j.rcim.2016.08.003 [13] 刘建坤.基于五自由度并联机构的隔振平台研究[D].哈尔滨: 哈尔滨工业大学, 2013: 7-19. http://cdmd.cnki.com.cn/article/cdmd-10213-1014080959.htmLIU J K.Research of a vibration isolation platform based on 5-DOF parallel mechanism[D].Harbin: Harbin Institute of Technology, 2013: 7-19(in Chinese). http://cdmd.cnki.com.cn/article/cdmd-10213-1014080959.htm [14] SUN T, SONG Y M, DONG G, et al.Optimal design of a parallel mechanism with three rotational degrees of freedom[J].Robotics and Computer-Integrated Manufacturing, 2012, 28:500-508. doi: 10.1016/j.rcim.2012.02.002 [15] 杨会, 房海蓉, 李典, 等.一种新型并联灌注机器人运动学分析和多目标优化[J].北京航空航天大学学报, 2018, 44(3):568-575. http://bhxb.buaa.edu.cn/CN/abstract/abstract14440.shtmlYANG H, FANG H R, LI D, et al.Kinematics analysis and multi-objective optimization of a novel parallel perfusion robot[J].Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(3):568-575(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract14440.shtml [16] XIE F, LIU X J, WANG J, et al.Kinematic optimization of a five degrees-of-freedom spatial parallel mechanism with large orien-tational workspace[J].Journal of Mechanisms and Robotics, 2017, 9(5):051005. doi: 10.1115/1.4037254 [17] LIU C H, LI R M, YAO Y A.An omnidirectional rolling 8U parallel mechanism[J].Journal of Mechanisms and Robotics, 2012, 4(3):034501. doi: 10.1115/1.4006657 [18] KONG X, GOSSELIN C M.Type synthesis of parallel mechanisms[M].Berlin:Springer, 2007. [19] JOSHI S A, TSAI L W.Jacobian analysis of limited-DOF parallel manipulators[J].Journal of Mechanical Design, 2002, 124(2):254-258. doi: 10.1115/1.1469549 [20] TSAI L W.Robot analysis and design:The mechanics of serial and parallel manipulators[M].New York:John Wiley & Sons, 1999. [21] 赵永生, 郑魁敬, 李秦川, 等.5-UPS/PRPU 5自由度并联机床运动学分析[J].机械工程学报, 2004, 40(2):12-16. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxgcxb200402003ZHAO Y S, ZHENG K J, LI Q C, et al.Kinematic analysis of 5-UPS/PRPU 5-DOF parallel machine tool[J].Journal of Mechanical Engineering, 2004, 40(2):12-16(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxgcxb200402003 -

下载:

下载: