Experimental study on film cooling of turbine blade leading edge in deposition environment

-

摘要:

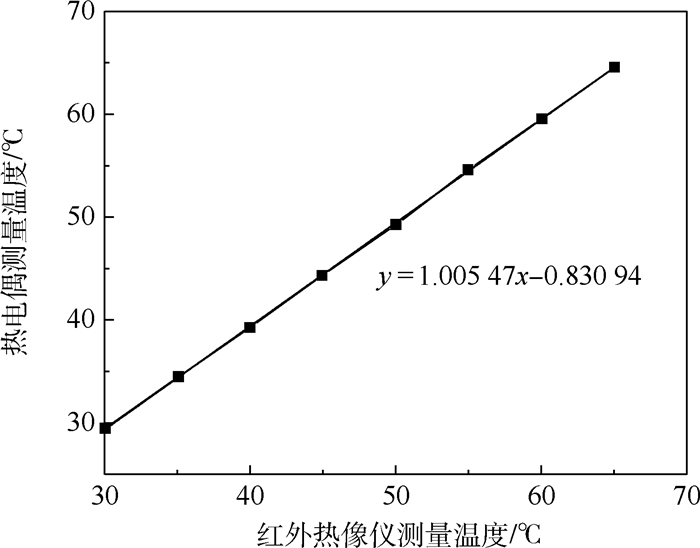

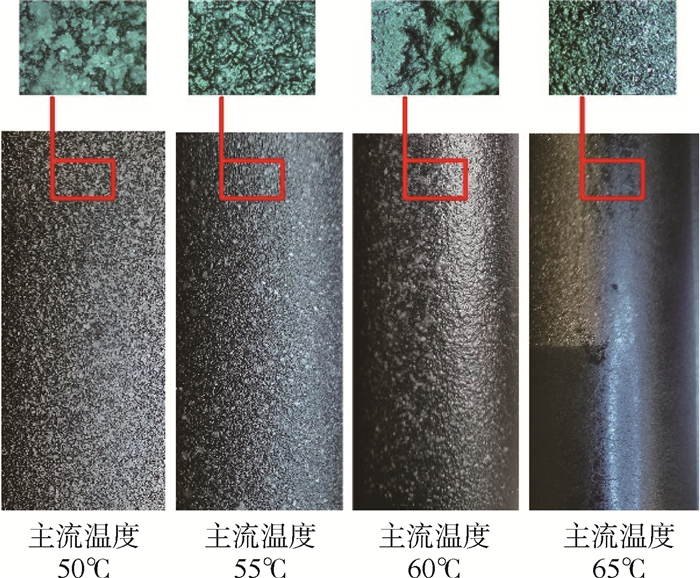

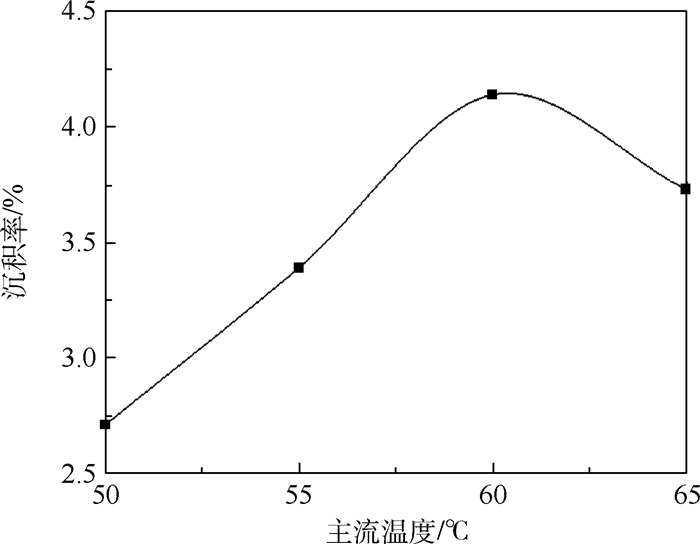

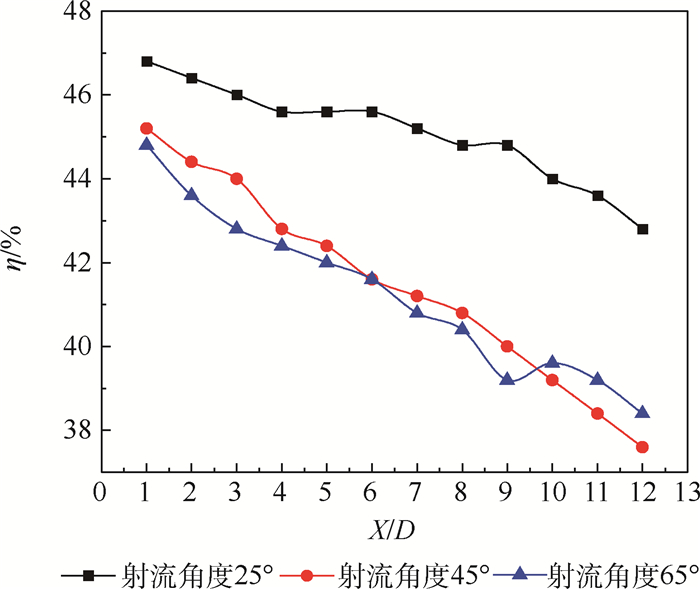

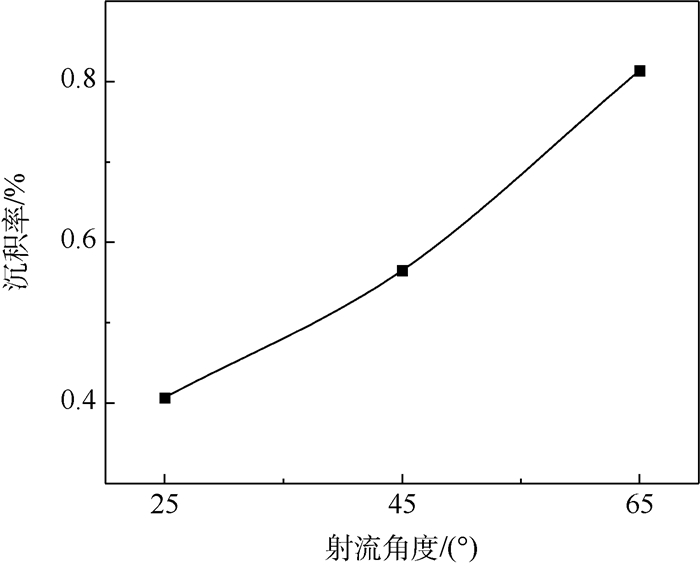

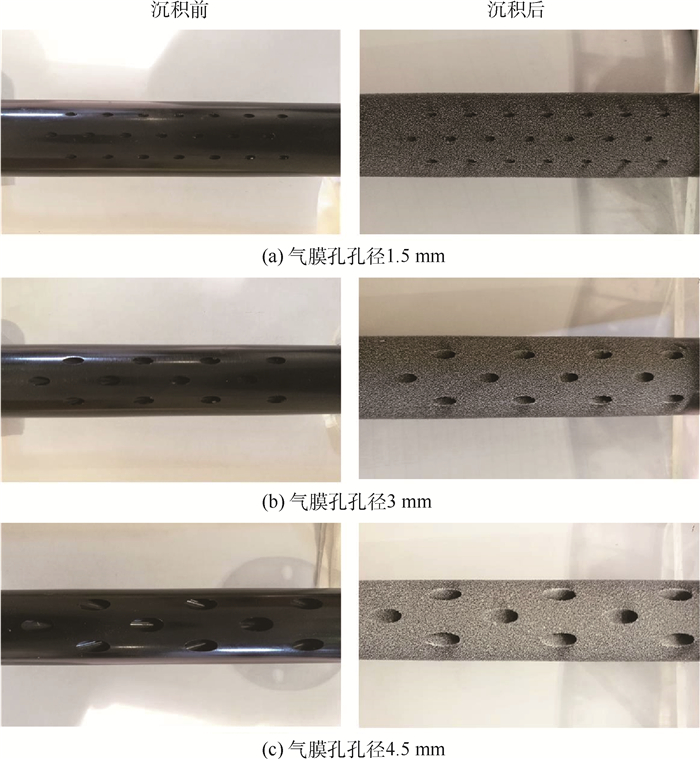

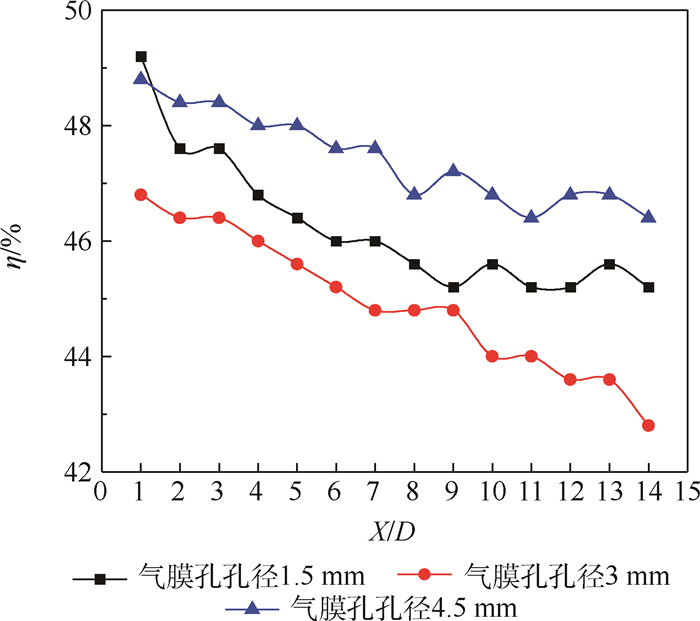

为研究沉积物对涡轮叶片前缘气膜冷却的影响,实验采用石蜡沉积模拟真实沉积。通过改变主流的温度、气膜孔射流角度及气膜孔孔径,观察了沉积环境下气膜冷却效率及沉积率的变化规律。实验结果表明:颗粒物沉积在障碍物表面的形貌受到主流温度的影响较大,当主流温度接近颗粒物熔点时,沉积覆盖最明显。在相同实验条件下,随着射流角度增大,单个气膜孔覆盖区域减小,气膜冷却效率下降,沉积前后,射流角度25°和65°的气膜冷却效率最大相差2%和5.6%,沉积率随射流角度的增大而升高;随着孔径增大,气膜冷却效率先降低后升高,其中4.5 mm孔径无论是否沉积,气膜冷却效率均最高,比3 mm孔径的气膜冷却效率高3.6%和3.2%。沉积率在孔径3 mm时最低。

Abstract:In order to study the effect of deposition of pollutants on film cooling of blade leading edge of turbine, the experiment used paraffin deposition to simulate real deposits.By changing the mainstream temperature, the angle of film hole jet and the diameter of film hole, the variation of film cooling efficiency and deposition rate in deposition environment was observed experimentally. The experimental results show that the morphology of particulate deposition on the barrier surface is significantly affected by the mainstream temperature. When the mainstream temperature approaches the melting point of particulate matter, the deposition coverage is most obvious. Under the same experimental conditions, with the increase of jet angle, the coverage area of single film hole decreases, and the film cooling efficiency decreases. Before and after deposition, the maximum difference between film cooling efficiency at jet angle 25° and jet angle 65° is 2% and 5.6%, and deposition rate increases with the increase of jet angle; with the increase of pore diameter, the film cooling efficiency first decreases and then increases. Whether there is deposition or not, the film cooling efficiency of 4.5 mm pore diameter is the highest, 3.6% and 3.2% higher than that of 3 mm pore diameter. The deposition rate is the lowest when the pore diameter is 3 mm.

-

Key words:

- film cooling /

- deposition rate /

- leading edge /

- pore diameter /

- jet angle

-

表 1 颗粒物性和缩放参数对照

Table 1. Contrast of particle properties and scaling parameters

参数 发动机 实验 颗粒粒径/μm 0.1~10 1~120 颗粒密度/(kg·m-3) 1 980[4] 900 颗粒速度/(m·s-1) 93[9] 3 动力黏度/(kg·(m·s)-1) 5.55×10-5 1.82×10-5 气膜孔直径/mm 0.5 3 熔解潜热/(J·kg-1) 650 000[18] 234 720 比热容/(J·(kg·K)-1) 730[19] 2 090 颗粒固化温度/K 1 533[20] 331.15 主流温度/K 1 500[21] 328.15 颗粒初始温度/K 1 593[21] 373.15 颗粒输运长度/m 0.26 1.5 Stk 0.004~40 0.003~40 TSP 0.012~1.2 0.02~2.8 -

[1] DUNN M G, PADOVA C, MOLLER J E, et al. Performance deterioration of a turbofan and a turbojet engine upon exposure to a dust environment[J]. Journal of Engineering for Gas Turbines and Power, 1987, 109(3): 336-343. doi: 10.1115/1.3240045 [2] KIM J, DUNN M G, BARAN A J, et al. Deposition of volcanic materials in the hot sections of two gas turbine engines[C]//ASME 1992 International Gas Turbine and Aeroengine Congress and Exposition. New York: ASME, 1992: V003T05A001. [3] JENSEN J W, SQUIRE S W, BONS J P, et al. Simulated land-based turbine deposits generated in an accelerated deposition facility[J]. Journal of Turbomachinery, 2005, 127(3): 462-470. doi: 10.1115/1.1860380 [4] BONS J P, CROSBY J, WAMMACK J E, et al. High-pressure turbine deposition in land-based gas turbines from various synfuels[J]. Journal of Engineering for Gas Turbines and Power, 2007, 129(1): 135-143. doi: 10.1115/1.2181181 [5] SUNDARAM N, BARRINGER M D, THOLE K A. Effects of deposits on film cooling of a vane endwall along the pressure side[J]. Journal of Turbomachinery, 2008, 130(4): 041006. doi: 10.1115/1.2812332 [6] CROSBY J M, LEWIS S, BONS J P, et al. Effects of temperature and particle size on deposition in land based turbines[J]. Journal of Engineering for Gas Turbines and Power, 2008, 130(5): 051503. doi: 10.1115/1.2903901 [7] AI W, LAYCOCK R G, RAPPLEYE D S, et al. Effect of particle size and trench configuration on deposition from fine coal flyash near film cooling holes[J]. Energy & Fuels, 2011, 25(3): 1066-1076. doi: 10.1021/ef101375g [8] SMITH C, BARKER B, CLUM C, et al. Deposition in a turbine cascade with combusting flow[C]//ASME Turbo Expo 2010: Power for Land, Sea, and Air. New York: ASME, 2010: 743-751. [9] LAWSON S A, THOLE K A. Simulations of multiphase particle deposition on endwall film-cooling[J]. Journal of Turbomachinery, 2012, 134(1): 011003. doi: 10.1115/1.4002962 [10] LAWSON S A, THOLE K A. Simulations of multiphase particle deposition on endwall film-cooling holes in transverse trenches[J]. Journal of Turbomachinery, 2012, 134(5): 051040. doi: 10.1115/1.4004756 [11] ALBERT J E, BOGARD D G. Experimental simulation of contaminant deposition on a film-cooled turbine vane pressure side with a trench[J]. Journal of Turbomachinery, 2013, 135(5): 051008. doi: 10.1115/1.4007821 [12] AI W, MURRAY N, FLETCHER T H, et al. Effect of hole spacing on deposition of fine coal flyash near film cooling holes[J]. Journal of Turbomachinery, 2012, 134(4): 041021. doi: 10.1115/1.4003717 [13] 杨晓军, 祝佳雄. 涡轮叶栅通道内颗粒物沉积过程的数值模拟[J]. 航空学报, 2017, 38(5): 31-42.YANG X J, ZHU J X. Numerical simulation of particle deposition process inside turbine cascade[J]. Acta Aeronautica et Astronautica Sinica, 2017, 38(5): 31-42(in Chinese). [14] 裴钰. 燃气轮机涡轮叶片表面污染物沉积模型研究[D]. 天津: 中国民航大学, 2015.PEI Y. Research of deposition model on blade surface of gas turbine[D]. Tianjin: Civil Aviation University of China, 2015(in Chinese). [15] 张斐, 刘振侠, 刘振刚, 等. 不同来流条件对涡轮叶片表面颗粒沉积影响的实验研究[J]. 推进技术, 2019, 40(7): 1536-1545.ZHANG F, LIU Z X, LIU Z G, et al. Experimental simulation of particle deposition on turbine blade surface with different free stream conditions[J]. Journal of Propulsion Technology, 2019, 40(7): 1536-1545(in Chinese). [16] 黄珂楠, 张靖周, 郭文. 气膜孔内局部堵塞对气膜冷却特性的影响[J]. 航空动力学报, 2014, 29(6): 1330-1338.HUANG K N, ZHANG J Z, GUO W. Effect of partial blockage inside film hole on film cooling characteristics[J]. Journal of Aerospace Power, 2014, 29(6): 1330-1338(in Chinese). [17] DAVIDSON F T, KISTENMACHER D A, BOGARD D G, et al. A study of deposition on a turbine vane with a thermal barrier coating and various film cooling geometries[J]. Journal of Turbomachinery, 2012, 136(4): 1769-1780. [18] LI R, WANG L, YANG T, et al. Investigation of MSWI fly ash melting characteristic by DSC-DTA[J]. Waste Management, 2007, 27(10): 1383-1392. doi: 10.1016/j.wasman.2006.11.017 [19] KRISHNAIAH S, SINGH D N. Determination of thermal properties of some supplementary cementing materials used in cement and concrete[J]. Construction and Building Materials, 2006, 20(3): 193-198. doi: 10.1016/j.conbuildmat.2004.10.001 [20] WANG Q, TIAN S, WANG Q, et al. Melting characteristics during the vitrification of MSWI fly ash with a pilot-scale diesel oil furnace[J]. Journal of Hazardous Materials, 2008, 160(2-3): 376-381. doi: 10.1016/j.jhazmat.2008.03.043 [21] DENNIS R A, SHELTON W W, LE P. Development of baseline performance values for turbines in existing IGCC applications[C]//ASME Turbo Expo 2007: Power for Land, Sea, and Air. New York: ASME, 2007: 1017-1049. [22] 刘晓红, 罗翔, 陶智. 大小孔交替排列对气膜冷却效率的影响[J]. 北京航空航天大学学报, 2010, 36(11): 1271-1274. https://bhxb.buaa.edu.cn/CN/Y2010/V36/I11/1271LIU X H, LUO X, TAO Z. The effect of alternate arrangement of big and small holes on film cooling efficiency[J]. Journal of Beijing University of Aeronautics and Astronautics, 2010, 36(11): 1271-1274(in Chinese). https://bhxb.buaa.edu.cn/CN/Y2010/V36/I11/1271 -

下载:

下载: